My summer season had a rather rough start. I went out for an overnight camp out on the crown land not far from home and found much to my dismay, that my tent was very wet inside and my mattress was soaked. I was extremely baffled by this, as I've had it out in heavy rains even while deployed, and never had water get in. I was forced to drag the mattress out and dry it by the fire, and wipe out the inside as best I could with the rags I had on board, and a bit of paper towel.

I checked it thoroughly when I got home and could see no way for water to get in. In talking later with a buddy of mine, he said he had the same issue with his Alucab tent, and it was caused by sudden changes in the weather producing large amounts of condensation. Hopefully a one off, but he installed vents on his tent to equalize the pressure, so I may give that a try.

Going from bad to worse, when I got home from the trip, I realized to my even greater dismay that the two front uprights of my bed rack had cracked at the top, one completely detached and one about 2/3s detached:

In thinking about this issue and how it could have happened, I figured that the side to side motion with the rooftop tent on put too much stress on these joints. I considered several options, like completely replacing my setup with something different, but I really like this setup and money is very tight. I also considered replacing the uprights and rebuilding the custom stuff onto the new ones, but even this was $218 if it was on sale, and more like $350 if not. I figured that even if I did buy new uprights, I would still want to add some bracing to the rack to prevent any side to side motion, and thus alleviate this cracking issue. In the end, I decided to "repair" the rack and add the bracing. Down the road, if I decide to replace the uprights, the bracing can very easily be added in from the start, preventing this situiaton from occuring again. After some thinking, I drew up a design based on aluminum angle and flat bar, bolted together and bolted through the top of the cross bar, through the brace, into the upper edge of the trussing:

You can also see in this photo the steel reinforced expoxy I used to glue the cracked uprights back together. Not perfect, but it's something.

This photo was taken just before the last flat bar was put in place and all the nuts torqued using the trusty german torque spec, "Gudentight."

The rack is now absolutely rock solid with zero side to side movement.

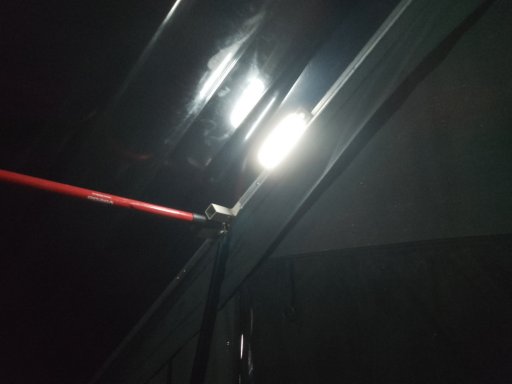

When taking the tent off, I had a friend come over and help me, but he's going through some difficult things right now, so I didn't want to trouble him. I came up with a novel solution to do it myself:

That's a farm gate we had laying around the property. I strapped it to the end of the bed rack with the blue straps, wrapped the chain around the sawhorse to secure it, and slid the tent up into position.

Cost of the repair/bracing was $90 for everything I had to buy, but that included the epoxy and a 240+ piece nut and bolt assortment, part of which I still have, so really it was less money.

Rumble is ready to ride again!