Will do, I will be doing a build report when I start. How hard would it be to make a skid? I have a plasma cutter, and metal brake etc. I am thinking, a cardboard cutout for a template, and go from there.

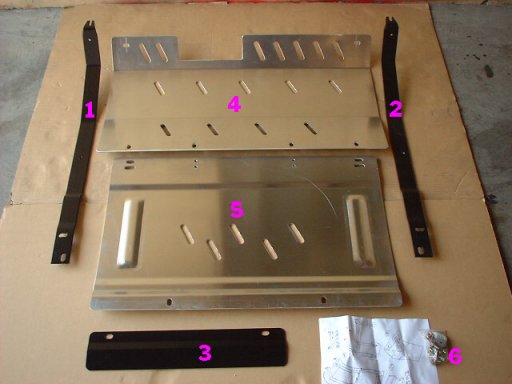

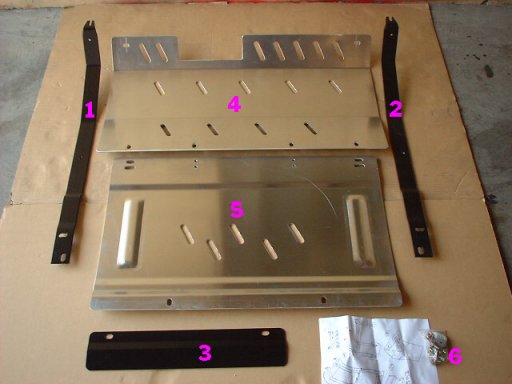

The FTS skid is two piece, with the plates bolted to two steel rails/springs that run parallel to the sides of the vehicle.

Pro: the two piece skid makes it easier to remove half to do an oil change. the springs give the plate a bit of resiliency.

Con: If both plates are removed, it is a pita to get all the holes lined back up, when laying on your back to get it all bolted back up. Also the FTS design does not secure the rear half of the rear skid to the vehicle. Instead, they provide a steel plate to reinforce the rear. I had two nuts welded to the chassis to actually secure the rear of the skid.

If I was to fab my own skid, for simplicity, I would ditch the steel rails/springs and make it one piece.

I concur that doing a cardboard mock-up is a great idea.

Start with welding some nuts over one of the three holes on each side of the chassis, just behind the transmission.

You can see the three holes here (two have nuts already welded, one has a bolt attached). You do not need two nuts/side (that was my faux-pas). I suppose if you wanted two nuts per side for extra beefiness, there's no harm in that. I would use the inner holes, rather than the outer hole to allow for a slightly narrower skid.

you can look at these pics to help with the shape.

While the FTS skid has numerous bends and bulges, You may be able to do the rear completely flat, with just one or two bends at the front to allow for attachment. Ventilation holes are optional, depending on temps at your locale.

The front attachment has two options.

1) since you cannot directly attach the front of the skid to the front mounting holes, you would need a short L shaped steel mounting bracket. One end bolts to the truck. The other end provides a mount location for the skid. The skid mounting hole can be drilled and threaded for the bolts, or maybe drilled with a nut welded to the backside to accept the bolt.

2) Find your own location(s) on the front to weld 2-3 nuts to secure the front of the skid. This may not be practical/possible and since my skid is installed, I can't look up there to give you any advice.

The cardboard mockup will help you determine location and number of bends.

While it will take a bit of effort, It's not too technical, and pretty much your only option, short of paying big buck$ to have a custom shop crank something out for you.

This type of skid configuration will provide basic protection for the oil sump and the transmission/transfer case. It is definitely "feel good" insurance to protect sensitive under-bits.

Good luck.