I had let this one go about 18 months. I usually try and do it once a year but I had gotten busy. The gas seems to have worked well even with the age. I use 2oz of Sta-bil for every can to keep it fresher longer. You can get a bottle of it for $12 and it will treat 80 gallons.How long do you usually store the fuel?

What Did You Do With Your Rig Today?

- Thread starter iamout

- Start date

-

Guest, UPDATE We went through the site migration runbook and completed all steps. We will need to complete the migration next week, but will leave the forums up for the weekend. A few days after maintenance, a major upgrade revision to the forum site will occur.

Member III

Yeah I use that stuff in the lawn mower during winter but I've never tried to store fuel in containers before. Might have to start going this route myself.I had let this one go about 18 months. I usually try and do it once a year but I had gotten busy. The gas seems to have worked well even with the age. I use 2oz of Sta-bil for every can to keep it fresher longer. You can get a bottle of it for $12 and it will treat 80 gallons.

Enthusiast III

Member III

- 2,827

- First Name

- Joshua

- Last Name

- Downs

- Member #

-

20468

- Ham/GMRS Callsign

- KK6RBI / WQYH678

- Service Branch

- USMC 03-16, FIRE/EMS

On the Jeep

Put a new spherical bearing and spring in the front drive shaft.

Put a new PL259 connector on my radio's coax

Installed caster adjustment shims on the lower control arms in an attempt to track down my front driveline vibes

Put a new spherical bearing and spring in the front drive shaft.

Put a new PL259 connector on my radio's coax

Installed caster adjustment shims on the lower control arms in an attempt to track down my front driveline vibes

Influencer III

- 4,312

- First Name

- Rex

- Last Name

- Drake

- Member #

-

19540

- Ham/GMRS Callsign

- KI5GH

- Service Branch

- Air Force

Member III

- 2,827

- First Name

- Jim

- Last Name

- covey sr

- Member #

-

16986

- Ham/GMRS Callsign

- none - BREAKER BREAKER HAND HELD CB AND WALKIE TALKIE

Slick install, I'm not good with this sort of thing so I appreciate your work.Fabricated and installed a bracket for the head unit on one of my ham radios. The prior owner removed the overhead console to mount the lights and sirens controllers. They did thoughtfully leave the mounting bracket so I had a hard point to rivet to. View attachment 128494View attachment 128496View attachment 128497View attachment 128498View attachment 128499

Member II

Today, I mounted a Andersen Power Connection to the top of the winch bumper, next to one of the grill-guard up-rights.. The cables from this connector is attached to the battery. It is part of a 20' jumper cable with Andersen quick connections.

The cable(with blue connector) is the power supply to the winch. I don't like to have the winch connected directly to the battery. You never know what can happen.

Yes, I could have installed a master cut-off switch, but I have limited space under the hood. Besides, I already had the quick connect Andersen jumper cables set.

If the winch is ever needed, I'll open the hood and pull the cable out from it's storage location, behind the grill and plug it into the Andersen connector.

Below is a pic of the winch power supply cable pulled from it storage location.

Winch cable in storage location, next to the hood latch.

Winch operating control cable connector mount behind grill.

Winch operating control cable attached to connector.

Below is the 20' jumper cable set with Andersen quick connector.

The cable(with blue connector) is the power supply to the winch. I don't like to have the winch connected directly to the battery. You never know what can happen.

Yes, I could have installed a master cut-off switch, but I have limited space under the hood. Besides, I already had the quick connect Andersen jumper cables set.

If the winch is ever needed, I'll open the hood and pull the cable out from it's storage location, behind the grill and plug it into the Andersen connector.

Below is a pic of the winch power supply cable pulled from it storage location.

Winch cable in storage location, next to the hood latch.

Winch operating control cable connector mount behind grill.

Winch operating control cable attached to connector.

Below is the 20' jumper cable set with Andersen quick connector.

Pathfinder I

Someday I'll get another winch with a rear hitch cradle and make a connector like that. Nice work.Today, I mounted a Andersen Power Connection to the top of the winch bumper, next to one of the grill-guard up-rights.. The cables from this connector is attached to the battery. It is part of a 20' jumper cable with Andersen quick connections.

View attachment 128572

The cable(with blue connector) is the power supply to the winch. I don't like to have the winch connected directly to the battery. You never know what can happen.

Yes, I could have installed a master cut-off switch, but I have limited space under the hood. Besides, I already had the quick connect Andersen jumper cables set.

View attachment 128576

If the winch is ever needed, I'll open the hood and pull the cable out from it's storage location, behind the grill and plug it into the Andersen connector.

View attachment 128577

Below is a pic of the winch power supply cable pulled from it storage location.

View attachment 128579

Winch cable in storage location, next to the hood latch.

View attachment 128580

Winch operating control cable connector mount behind grill.

View attachment 128581

Winch operating control cable attached to connector.

View attachment 128583

Below is the 20' jumper cable set with Andersen quick connector.

View attachment 128584

Member II

I also plan to buy another winch to do the same(rear hitch receiver mount). I have another set of these cables to do so.Someday I'll get another winch with a rear hitch cradle and make a connector like that. Nice work.

Enthusiast III

Influencer III

- 4,312

- First Name

- Rex

- Last Name

- Drake

- Member #

-

19540

- Ham/GMRS Callsign

- KI5GH

- Service Branch

- Air Force

Thanks, I've been trying to make use of the space for a while, and finally had an epiphany. After that it was easy.Slick install, I'm not good with this sort of thing so I appreciate your work.

Did you buy the jumper cables with ends on them already, or modify a set. I've been meaning to add connections out my grill for jump points just havent taken the time. Looks good, clean install!Today, I mounted a Andersen Power Connection to the top of the winch bumper, next to one of the grill-guard up-rights.. The cables from this connector is attached to the battery. It is part of a 20' jumper cable with Andersen quick connections.

View attachment 128572

The cable(with blue connector) is the power supply to the winch. I don't like to have the winch connected directly to the battery. You never know what can happen.

Yes, I could have installed a master cut-off switch, but I have limited space under the hood. Besides, I already had the quick connect Andersen jumper cables set.

View attachment 128576

If the winch is ever needed, I'll open the hood and pull the cable out from it's storage location, behind the grill and plug it into the Andersen connector.

View attachment 128577

Below is a pic of the winch power supply cable pulled from it storage location.

View attachment 128579

Winch cable in storage location, next to the hood latch.

View attachment 128580

Winch operating control cable connector mount behind grill.

View attachment 128581

Winch operating control cable attached to connector.

View attachment 128583

Below is the 20' jumper cable set with Andersen quick connector.

View attachment 128584

Enthusiast III

Excellent call. The first thing I installed on my Tacoma was a set of RCI rock sliders in preparation for an upcoming Moab trip (Jeep was down due to shoddy work by a local shop, eventually repaired by myself but not in time for the trip). We didn’t do any red trails but returning on the Colorado River overlook trail in Needles, the right rear tire slipped off a rock and the kick out portion of the slider stopped the side of the truck from slamming into a vertical rock wall. Boom, $$$ spent justified!Today the project of converting heavy steel steps to true rock sliders welded to the frame was completed. My truck was not built for rock crawling but there's always the possibility of that "oh crap" moment coming down off a ledge or something. This will definitely save the rocker panels.View attachment 128591View attachment 128591

Member III

- 2,827

- First Name

- Jim

- Last Name

- covey sr

- Member #

-

16986

- Ham/GMRS Callsign

- none - BREAKER BREAKER HAND HELD CB AND WALKIE TALKIE

You need not make excuses for adding protection to your vehicle. Rocks are not the only way to damage the rockers. I like the insurance myself. Cheaper than a body shop by far.Today the project of converting heavy steel steps to true rock sliders welded to the frame was completed. My truck was not built for rock crawling but there's always the possibility of that "oh crap" moment coming down off a ledge or something. This will definitely save the rocker panels.View attachment 128591View attachment 128591

Member III

- 2,827

- First Name

- Jim

- Last Name

- covey sr

- Member #

-

16986

- Ham/GMRS Callsign

- none - BREAKER BREAKER HAND HELD CB AND WALKIE TALKIE

You can send some my way ! :-)Thanks, I've been trying to make use of the space for a while, and finally had an epiphany. After that it was easy.

Member II

I used to install these on Service Trucks. I've been having a couple set from before I retired. They were bought from NAPA. They're not cheap. If I were to purchase more, I'd shop Amazon. They sell these in many lengths.Did you buy the jumper cables with ends on them already, or modify a set. I've been meaning to add connections out my grill for jump points just havent taken the time. Looks good, clean install!

Member II

That there is some fine sliders.Today the project of converting heavy steel steps to true rock sliders welded to the frame was completed. My truck was not built for rock crawling but there's always the possibility of that "oh crap" moment coming down off a ledge or something. This will definitely save the rocker panels.View attachment 128591

Pathfinder I

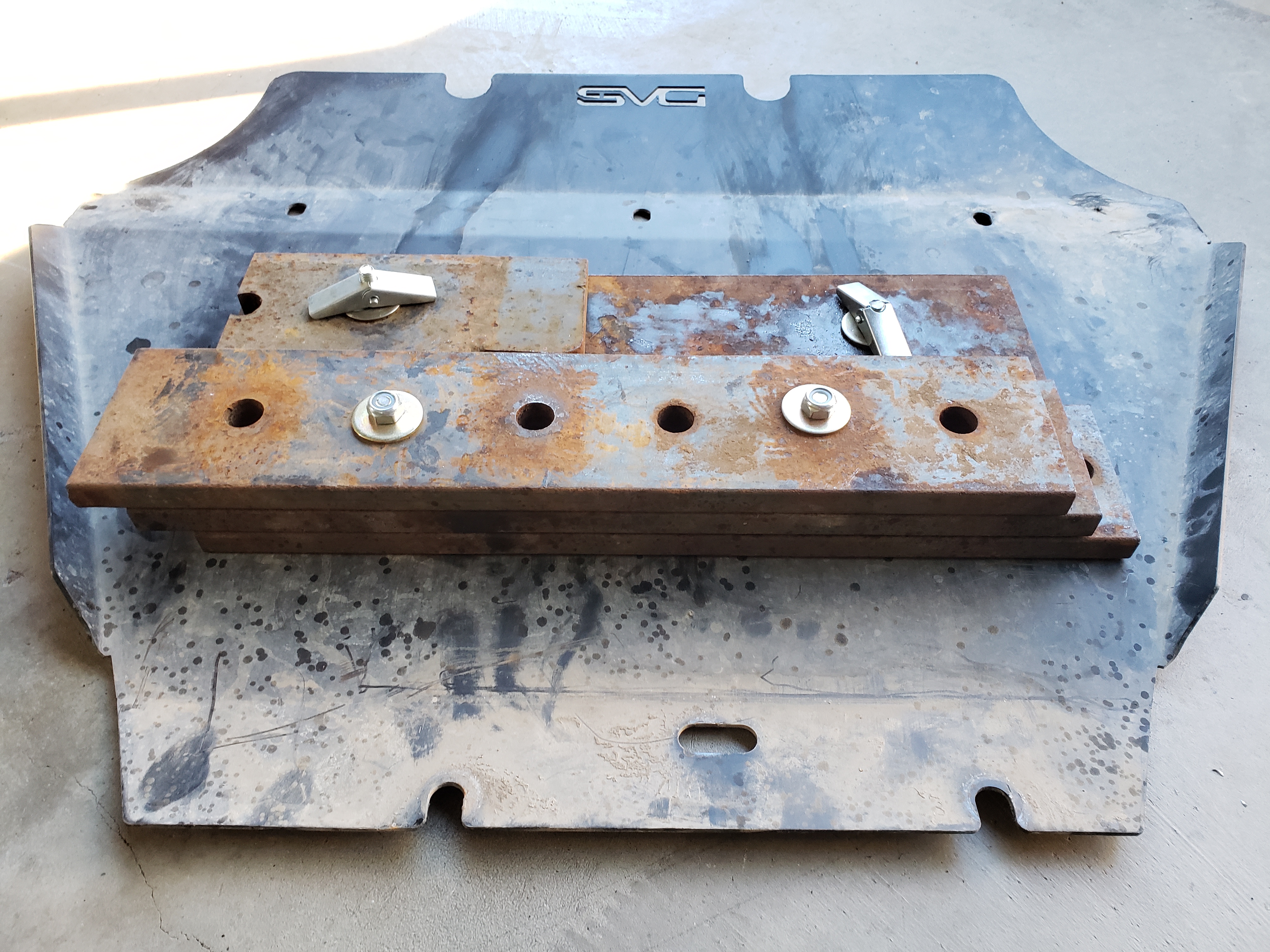

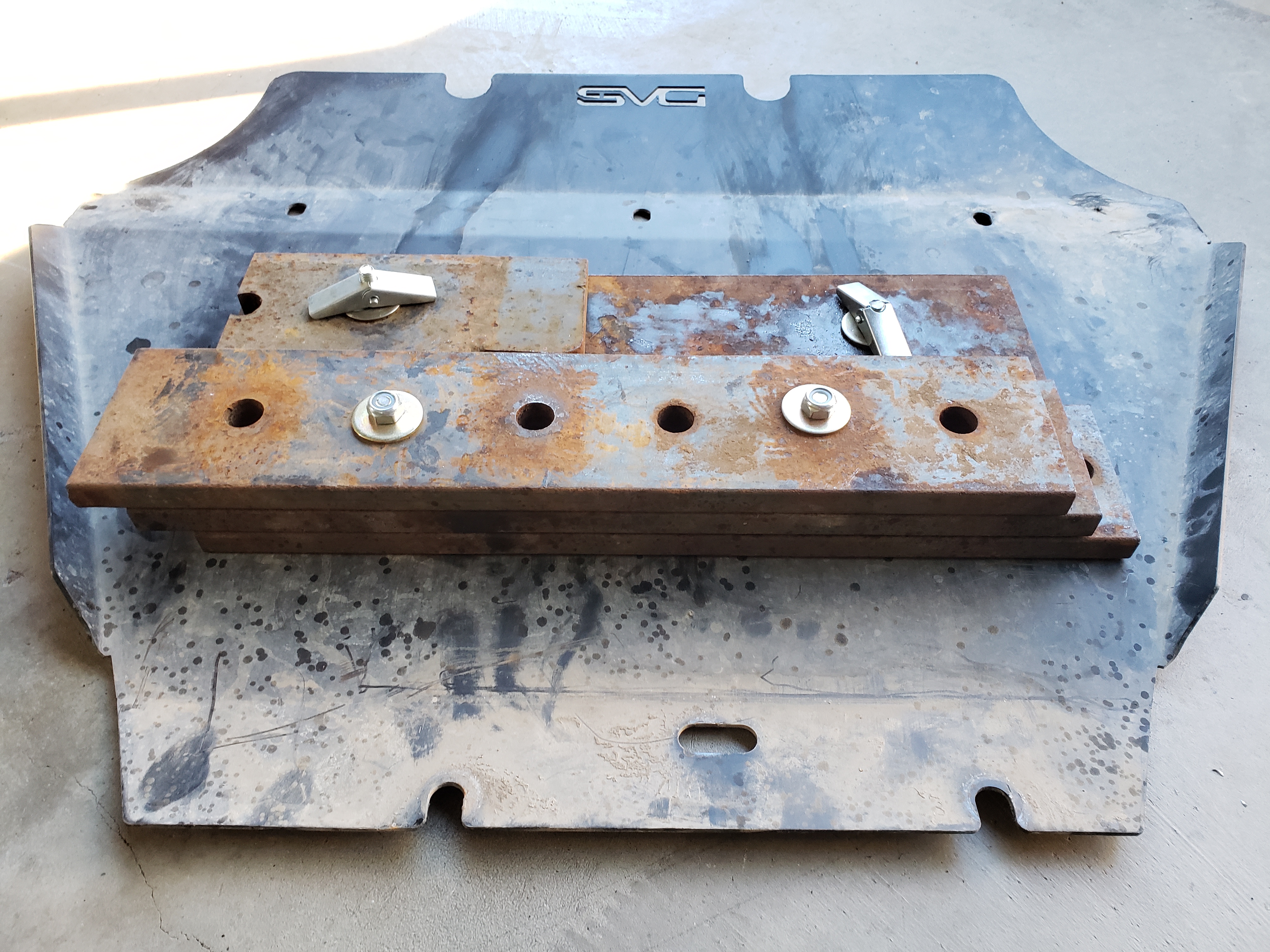

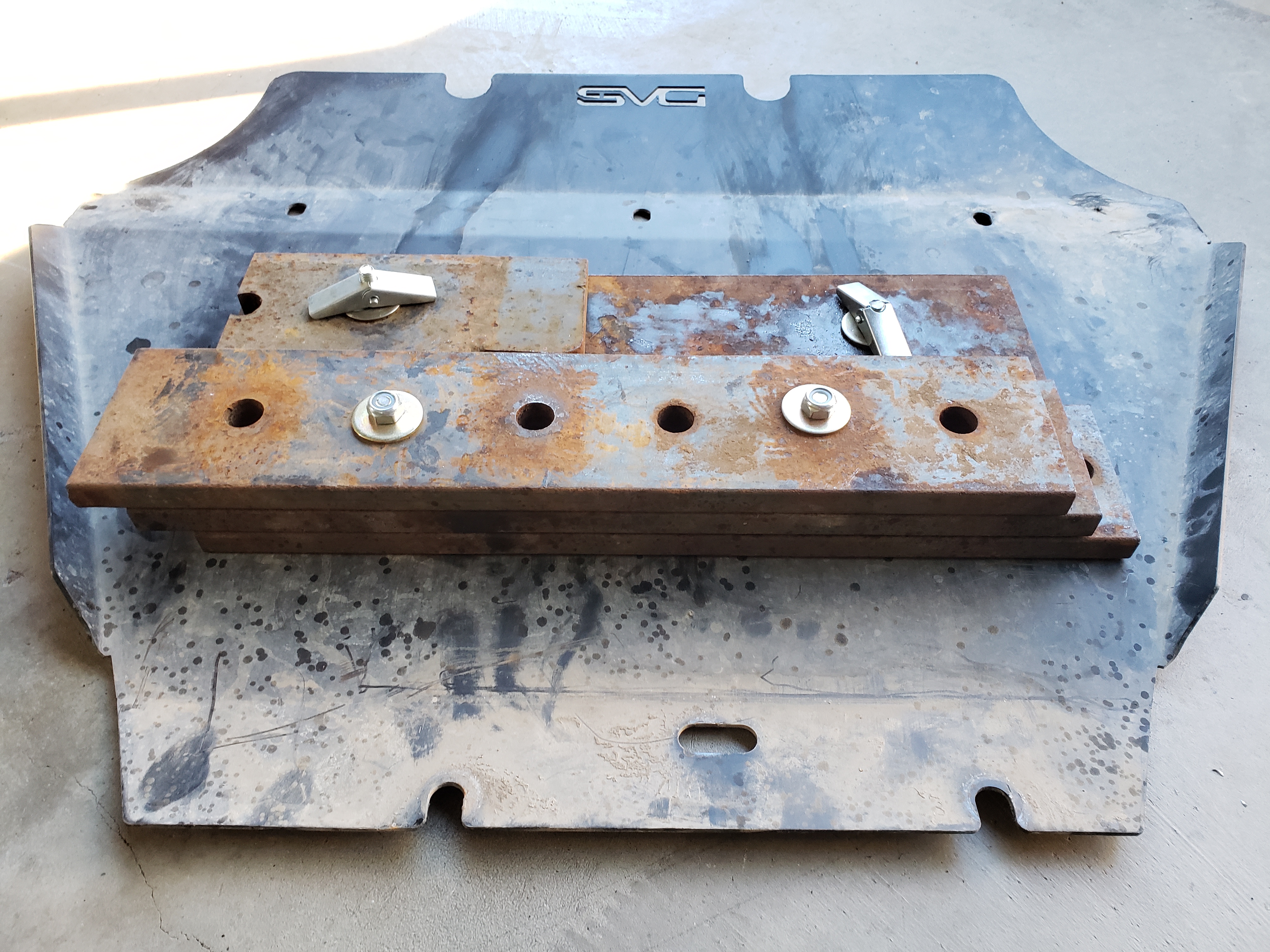

Because Accutune didn't offer to swap out my springs for lower rate coils and because I'm refuse to spend $200 on a new set.......

Here's about 100lbs+ worth of steel plates bolted to the "inside" of my front skid to weigh the front down. I ran out of nylon lock nuts so used wall anchors temporarily. Livin' ghetto fabulous over herrr........

Here's about 100lbs+ worth of steel plates bolted to the "inside" of my front skid to weigh the front down. I ran out of nylon lock nuts so used wall anchors temporarily. Livin' ghetto fabulous over herrr........

Member III

- 2,827

- First Name

- Jim

- Last Name

- covey sr

- Member #

-

16986

- Ham/GMRS Callsign

- none - BREAKER BREAKER HAND HELD CB AND WALKIE TALKIE

Why was this necessary, too high, too stiff ??Because Accutune didn't offer to swap out my springs for lower rate coils and because I'm refuse to spend $200 on a new set.......

Here's about 100lbs+ worth of steel plates bolted to the "inside" of my front skid to weigh the front down. I ran out of nylon lock nuts so used wall anchors temporarily. Livin' ghetto fabulous over herrr........

There should be a better solution than adding that much weight. Have you thought about cutting a coil or heating the coil ? What kind of springs do you have, leaf or coil ?