Enthusiast III

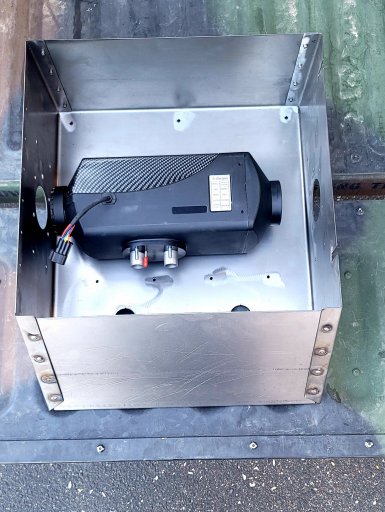

The enclosure I'm designing for it has a shelf with the cutouts for the inlet/exhaust manifold on the diesel heater. And the fuel pump mount at 45 degrees, I was reading that it is optimal to have the pump at that angle, fuel filter mounts in the vertical orientation I believe. I need to figure out a good way to duct the heated air out the side with some type of PVC bulkhead so I can easily cap it for storage/transit.

From what I've read these oil/fuel pumps don't have much suction head capacity, only around 12 inches, but they can push fuel uphill quite far. I might design the pump into a screw-on ring that matches the fuel can, that way it will only have to prime about 12 inches and then push uphill for 24ish inches. Some testing will be required to make sure this actually works.

From what I've read these oil/fuel pumps don't have much suction head capacity, only around 12 inches, but they can push fuel uphill quite far. I might design the pump into a screw-on ring that matches the fuel can, that way it will only have to prime about 12 inches and then push uphill for 24ish inches. Some testing will be required to make sure this actually works.