Advocate III

- 5,584

- First Name

- Michael

- Last Name

- Rose

- Member #

-

20990

- Ham/GMRS Callsign

- W7FSB

- Service Branch

- US ARMY Retired

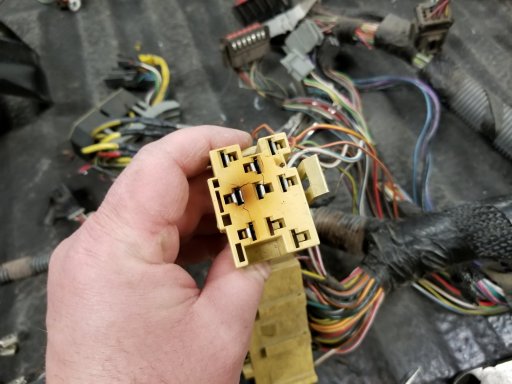

When you are done with your 84, you want to do my 89?Thanks. My chiropractor has been liking all the extra hours and work. It's a good thing I don't sleep much normally! Probably being more fussy than I need to be for it's intended purpose. But the hope is that it will last for awhile.