Whew haven't updated on the YJ in a while. Haven't covered this project as close as the CJ5 or 2A.

Drove an hour north and scooped up the correct style of steel wheel for this year and trim package. I was about to give up and buy some refurbs from ROCKAUTO but stumbled across these for 60 dollars for a set of 4. I was very surprised when I picked them up, they had some cobwebs and grass stuck on them but overall if they hadn't had wheel weights still on them, I would have never guessed they had ever been used. They didn't even have tire gunk on the bead sealing areas from previous tires. Even had 3 of the 4 center caps.

I hauled them back threw them in the back of the YJ then ran to Discount Tire and had them mount and balance a new set of Goodyear Wrangler Trailrunners, I currently run these on my XJ for daily use, and they have been great on road and decent enough off pavement. I've always got my mud terrains on a seperate set of steel wheels for the times I'll be spending more time off than on road.

On the downside I lost one of my hubcaps. It looks like one of their workers forgot to snug down the screws, it got launched going down the road and got destroyed by a passing car. I have a request to them now to look at replacing it. I had spares on the wheels they took off so I stole another one from the off road tire set.

View attachment 258892

Prior to that.

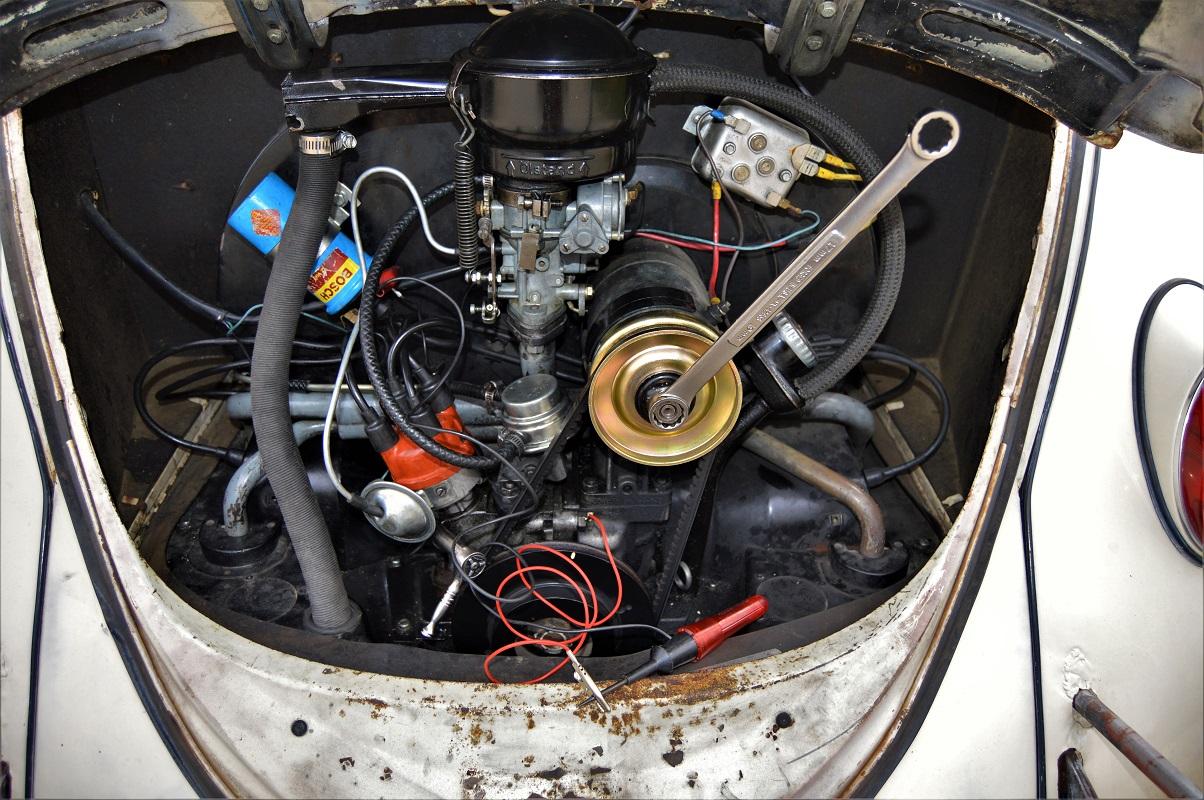

Got some more work done on the YJ yesterday. A decent chunk. Buttoned up the rear end and refilled, changed fluids in Trans and T-case. Found the wrong fluid in the T-Case. Not entirely sure what it was, but it wasn't ATF. Refilled with the proper fluid there and changed the trans out to 15W40. GL4 80W90 is a **** to find locally and my old online source the cost has gone up dramatically. Later in the AX5s life they would respec it for engine oil anyway and on a viscosity chart 15W40 is really close (a little heavier) than 80W90.

The previous owners had put a metal shift knob in. When I removed it, I saw why. They had broken off the threaded part of the shifter at some point and just put some aftermarket part on it instead. I ground down what was left of the stud flush with the top of the shifter then took a metric bolt that fit the OEM replacement knob I had and cut that down to the length I needed so all I had was a stud, then I welded that as square as I could to the top of the shift handle, cleaned it up with a flap wheel and hit it with a little paint then installed the replacement knob.

My brother was here (who I bought this from) and we took the Jeep out for a 20-minute drive on back roads. When I got back, I found the front driver's brake was sticking. I pulled the wheel off and disassembled it and found where the pads ride on the knuckle had notches worn in them preventing the inside pad from backing off of the rotor. It's also not uncommon for these calipers to stick, but I decided I would fix the notches and try again. So out came the little HF flux core welder again, and I filled the notches in, then took the flap disc and ground them down and profiled them to match up with the rest of the area. Threw everything back together after a bit of brake grease and pumped the brakes back up. They seem to be releasing now, but I was unable to take it back out for a test drive at that time, so not sure if I'll need to swap calipers yet.

I'm still waiting for some shift tower parts, oil pressure sensor, I still need to figure out the rear brake lights as far as going back to the standard style Wrangler taillights, and I still have some cleaning to do in various areas and I need to get my "Fat 50" ammo can mounted as a center storage between the seats but overall she's coming together nicely.

A couple of days ago, I replaced the brake caliper on the driver's side of the YJ. It was for sure sticking, but it was a little better with the notches filled in. Day before yesterday I replaced the alternator, which was making good power output but had a bearing going on in the rear and was making a squealing/squeaking noise at anything engine speeds over idle. I also put a new oil pressure sensor in. For whatever reason one of the previous owners decided to remove the oil pressure sensor and replace it with a bolt with about 1 inch of RTV slathered around it. The oil pressure gauge in the cap was pegged out so I figured the sensor was broken, didn't expect to find it completely gone, ha.

What's wild is they spent more time/effort with their "Fix" than just putting a new sensor in.