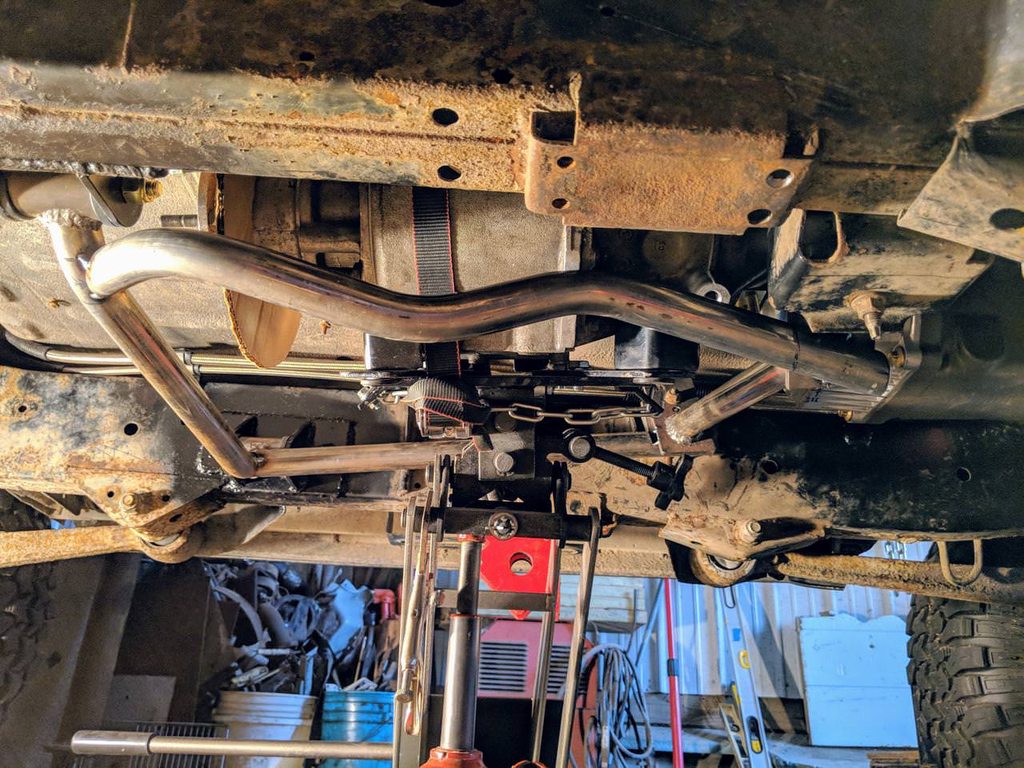

Now that there's not a choking cloud of

ready-to-explode gasoline fumes under the truck... I can get back to work on the divorced transfer-case crossmember!

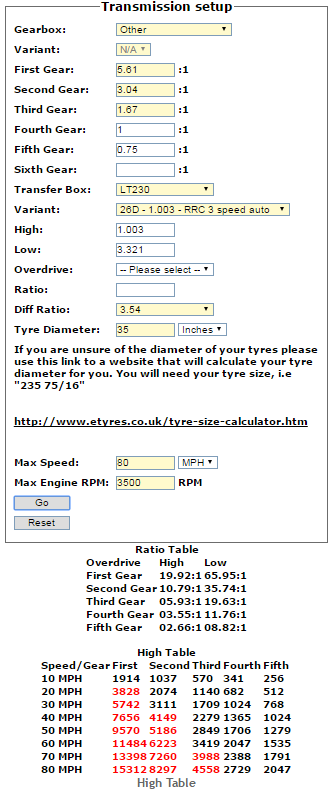

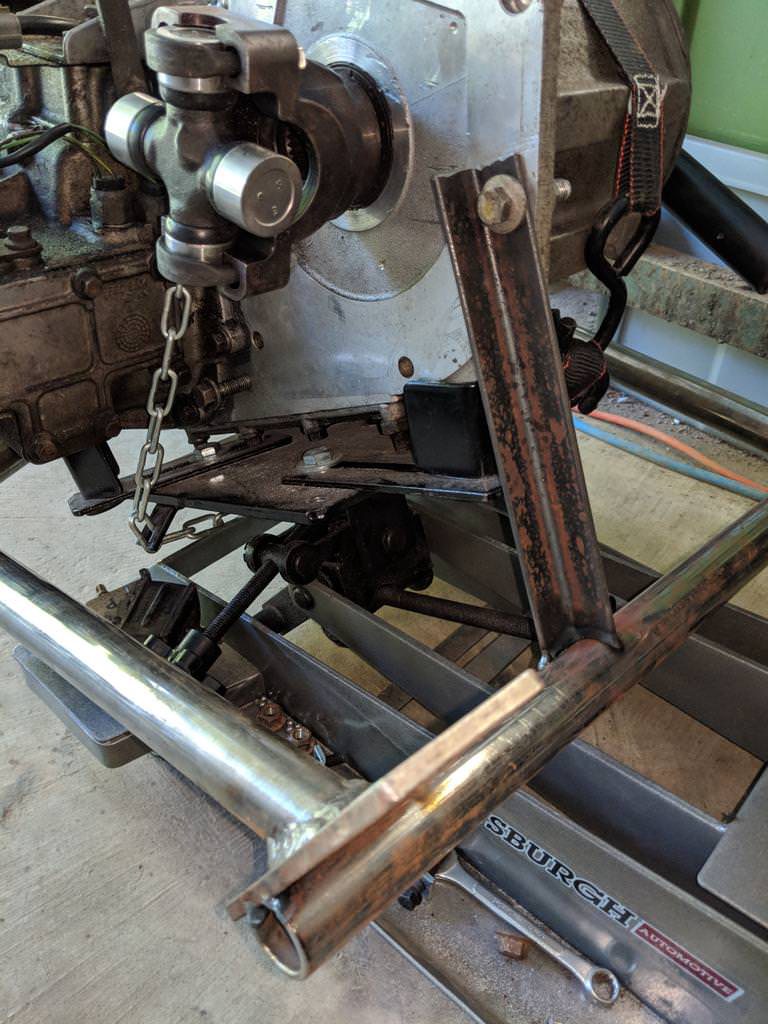

First order of business was to be sure the whole assembly was as level & straight as I could manage. Good thing I'm paranoid about getting it all really straight, because I forgot I had left the engine mount studs finger tight & it wiggled its way a bit crooked. Much better now:

Luckily the input face of the transfer-case has a large & flat machined surface

(that used to be where it mated to the old transmission) so that I can accurately measure the yokes are dead straight:

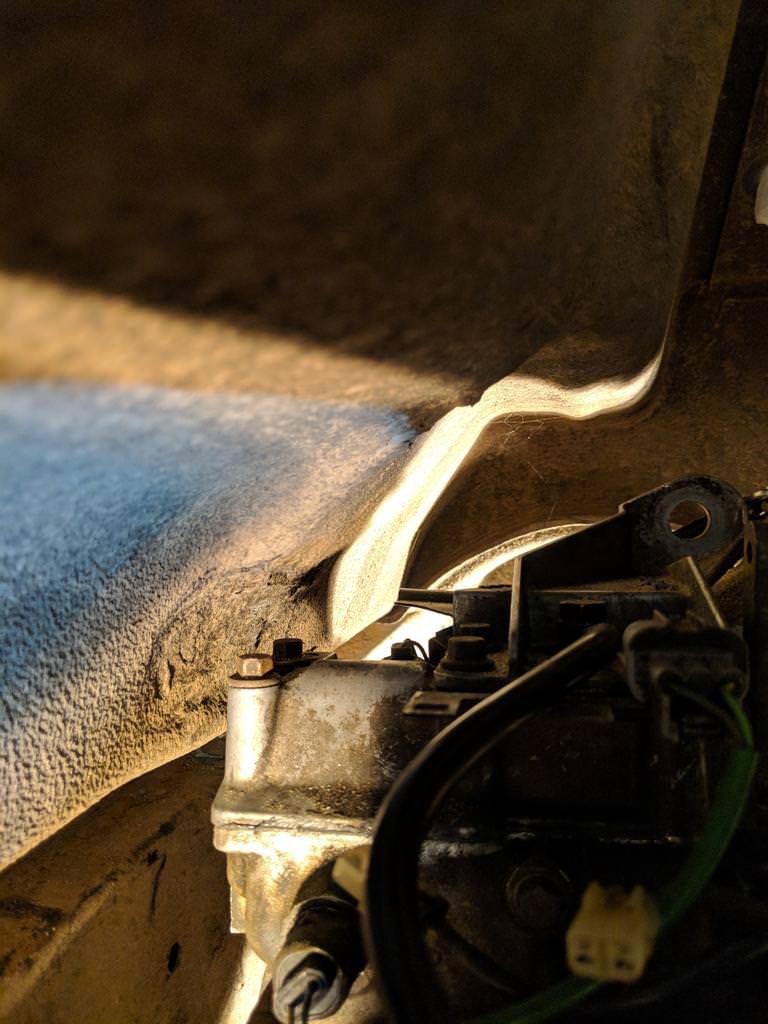

Started by making up a pair of plates to mesh with the old drivetrain isolaters on the frame, these will make up the forward half of the mounts:

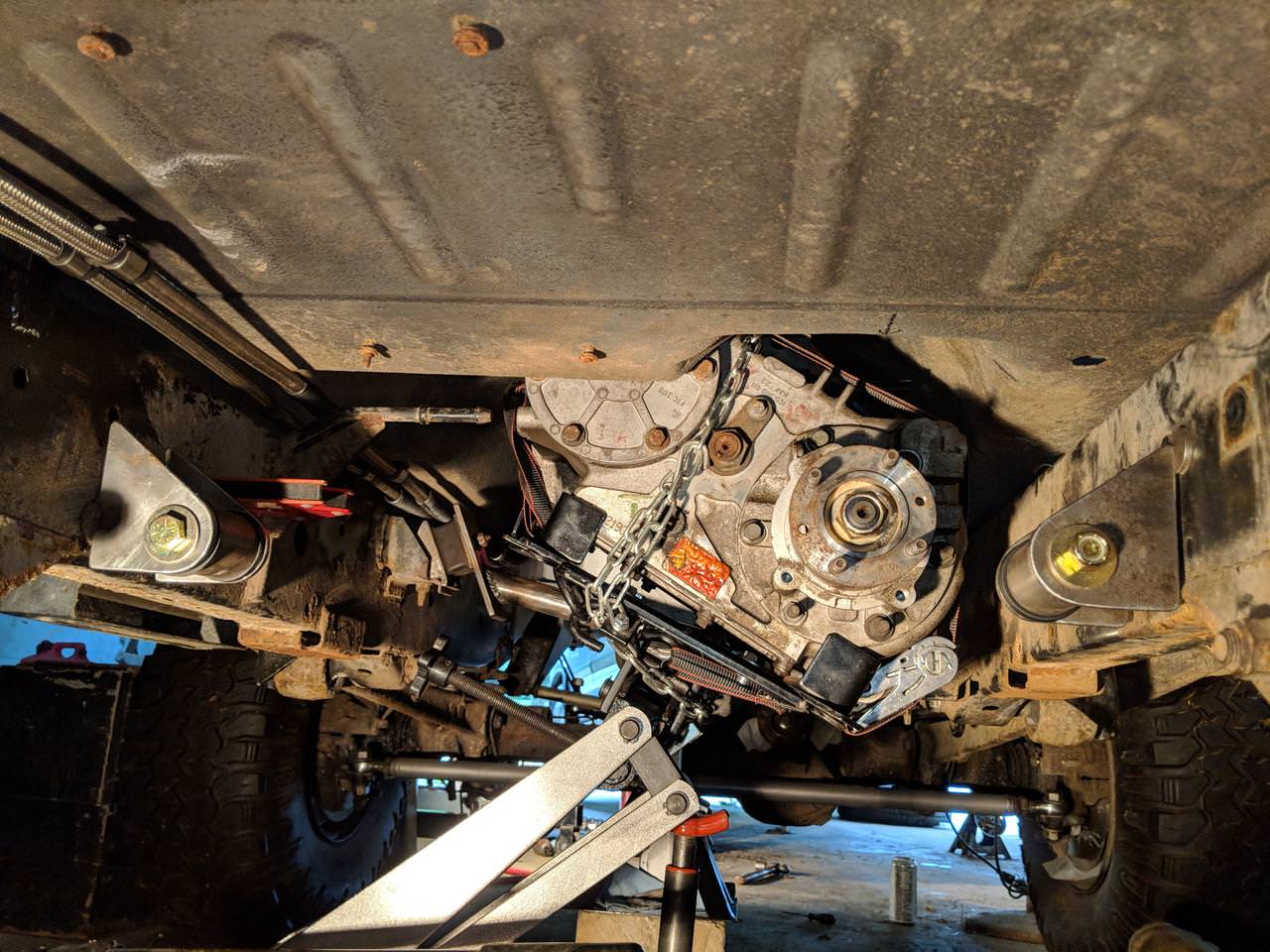

The transfer-case & transmission will be bolted

nearly solid to this crossmember I'm building, then the crossmember will be rubber mounted to the frame. The idea is to limit movement between the transfer case & transmission by linking them together. For the sake of reducing deflection in the u-joint between them under high torque loads, while still reducing

some vibration transmitted to the frame. AND if I do it right then it'll be easy to work on by dropping out as a unit & staying out of the way of any areas that need maintenance/visual-checks from time to time.

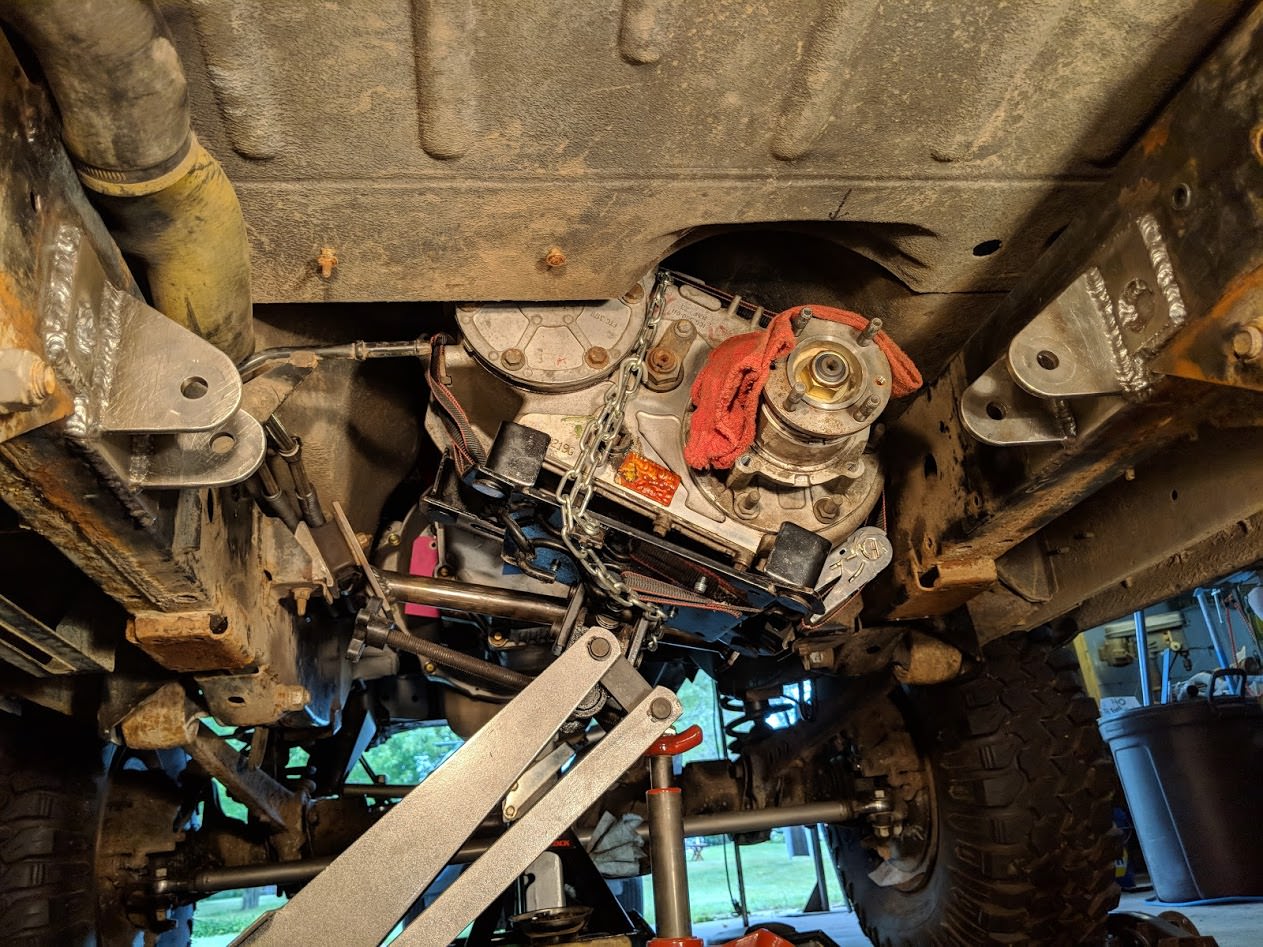

The crossmember will be constructed of 1/4" plate & 1.25" DOM tube, forming a box with an "X" inside if all goes to plan:

Next up I'll build the rear half, which will be more complex, requiring a new pair of tabs welded to the frame rails. Forward connection's all burned in: