Member III

It is pretty easy. A complete parts list would depend on your rig and how you want to do it.Charles, thank you for putting this thread together! Lots of ideas and great information.

I have been willing to build an air up/down system similar to yours for some time now. Could you share more details about it, and maybe parts needed? Was it difficult to assemble?

Thank you!

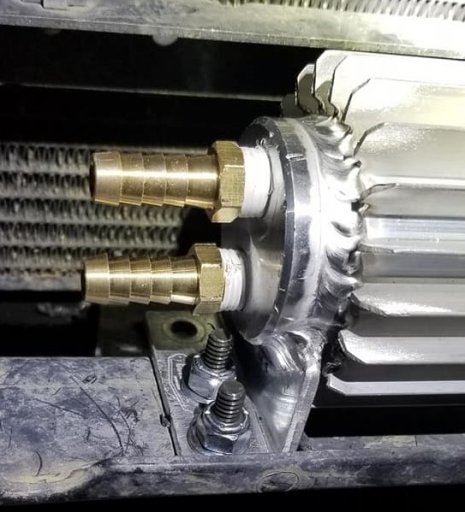

Refering to the photo below... The bottom hose when dis-connected lets the air out when you air up it connects to the air supply. In my rig that is a CO2 tank or a back up air pump.

Going from the bottom hose up it goes into a ball valve, into a 3 way distribution block. The block has a standard air gauge (1 pound increments 0 to 60) screwed into one hole the other two outlet holes have quick connects in them for airlines to plug into.

This is an old photo with the air lines plugged into the 3 way. My set up now has a single line running from the back to mid -vehicle with a T - fitting and hoses to each side door terminating into female quick connects . So this three way is in the back beside the tank now.

Each side hose assembly will have the following. T-fitting with a male quick connect for plugging into the connector at the side door, two hoses with Haltec H- 5265 standard bore locking (closed) air chucks on the ends. The closed chucks only allow air to pass when connected. These connectors have three locking lugs instead on just one. They will not fall off when connected properly. Hoses... If you use CO2 you want to use heavy duty reinforced hose because if you get liquid CO2 in the lines it can cause the lines to fail.... If you have an air pump any line will work. I use heavy lines so I can cut them to length and use crimp on clamps. Check out the following photo and feel free to ask any other questions.

Most of the parts can be found at Harbor freight except the air chucks, you can get them on Amazon.

Attachments

-

66.5 KB Views: 114