2023

Addressing sound and heat. Luckily for me theres a lot of good science on these topics. There is also a lot of misunderstanding on the internet it turns out. People seem to be pretty passionate about this as well. I think it's because so much is at stake and it becomes an ideology. For me, I am doing the best I can...mistakes will be made. I enjoy the research and the process. Honestly, being disabled mean I spend way too much time in bed unable to do the things I want...so I dont mind taking it slow and getting it done "right"

Also, science being science...our understandings change with experiments and experience. Here is what I've come up with.

For sound, we need to address mechanical vibrations and airborne sound, which is compressive forces on air. The higher the Hz (pitch) the easier to deal with as these are shorter waves and less "deep" than lower octaves. Having a V8 doesn't help. Having big treaded tires doesn't help. having large metal panels doesn't help. US submarines need to be silent, for I hope obvious reasons. All politics aside, there's a lot of science that has been developed to deal with sound and vibrations. One of the most effective systems (and all of these things should be thought of as systems) is the use of constrained layers. Think of it like a sandwich of two ridged layers with a forgiving middle layer. Now I am way oversimplifying all this of course, but if you are looking for quiet...the system I've implemented works pretty well. Unfortunately it adds weight. Compromise is everywhere.

I have already shown some of the work done and for convenience will just list it here.

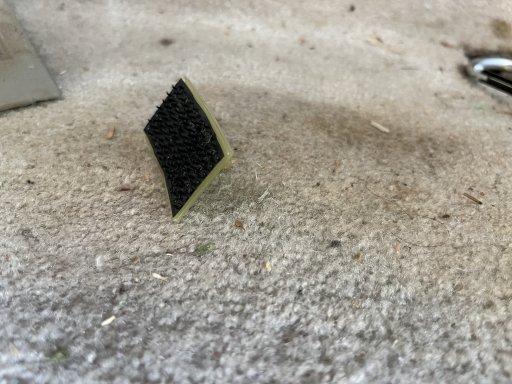

1. constrained layer, or dampening mats for mechanical vibration, made from butyl and aluminum sheet, the butyl sticks to the metal panel and created the constrained layer, the thicker the aluminum sheet the better.

2. Viscoelastic, layer this on top as overkill for the dampening of mechanical vibrations. The product used includes anti corrosive agents and pretty effectively seals the area from water and oxygen intrusion as well. This layer adds some mass, but mostly absorbs vibrations and releases that energy as tiny amounts of heat.

3. closed cell foam glued to mass loaded vinyl. Not shown yet, still a ways away from that step...this layer is the layer that does what everyone seems to think the constrained layer does. This layer effectively addresses airborne waves. The foam blocks many of the higher frequencies and the mass loaded vinyl that is attached addresses lower waves. Because the foam is a forgiving layer and the vinyl less so, it acts as another constrained layer, allowing the vinyl to move and absorb most of the frequencies. Added benefit of the foam is thermal effective barrier as well. With this layer, you really want 100% coverage, overlapping here is a good idea, and aluminum tape for any seams...this isn't the layer to skimp on.

For thermal insulation, there is also a lot of good science (hey wha'd'ya know?!) There are three main things to address here (which bring up other issues). Heat can be classified into two main types: sensible heat, which can be felt and measured, and latent heat, which is absorbed or released during a change of state, such as melting or vaporization (think here also of heat soak). Additionally, heat transfer occurs through three mechanisms: conduction, convection, and radiation. We need to address these in ways that are effective.

To address these in my vehicle, I chose the following systems.

1. 1/4" closed cell flame retardant vehicle foam. This addresses direct conduction and stops thermal bridging. I am not particularly happy to use foams but this is the best I found for what I need to address, the other bonus is again sound absorption. (this also effectively acts as a vapor barrier, we can get into that later)

2. 3M SM600L Thinsulate (Compromises: I don't believe 3M when they say this is neutral to health, and I dont like 3M politics, but their products are too effective to ignore here. ) This was designed for acoustic insulation, so added bonus, but has been found to be very effective for stopping convection. I had been thinking of using mineral wool, and do use it in a couple small spots, but this is a better fit for our needs.

3. aluminized foam as the radiant barrier, not the bubble wrap "reflectix" but the same idea at least. This layer, more than the others really depends on proper installation for effectiveness, a lot of people using it and getting minimal effective value. For our use, we have this layer glued to the thinsulate, which acts as a 4" air gap. Both sides are aluminized.

This system isn't static either, it changes around the vehicle dependent on how that location needs to be addressed.

Here is how we addressed the tailgate...not an easy one.