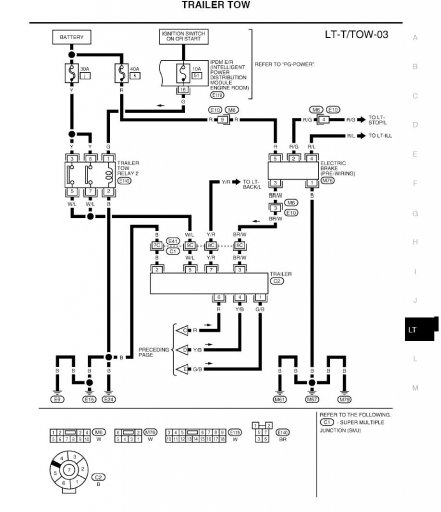

OK, I'm totally baffled....I did some checking on my truck...2018 RAM 2500 with snowprep and tow package. This gives me a 220a alternator and a trailer brake controller with 7 pin trailer plug. A bit of research and I'm finding that pin #4, using a 10g factory installed wire, has a 30A fuse at the fuse box. This wire is about 25' in length from my eyeball observation.

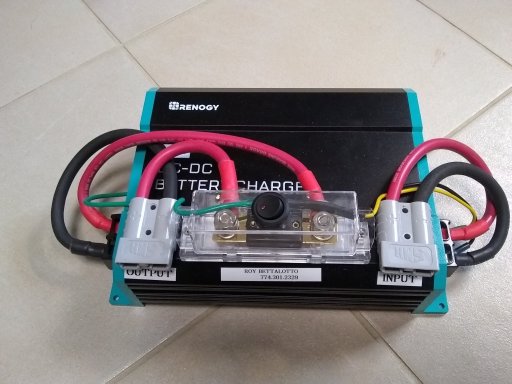

But, RENOGY recommends , for a 25' run from front of vehicle to the back, with the 40a DC to DC charger, that you use 4awg wire???? And for the 20A DC to DC charger you use 6awg.......

The "Engineering Tool Box"

Amps and Wire Gauge in 12V Electrical Circuits says a 10g wire at 25' will only handle 10 amps ....But remember, for a 12V system you need to add the supply and return, which would be 40-50'. At 50' a 10g wire will only handle 8A, which is what I've measured many times.

I'm not sure is the 7pin plug on my truck uses the chassis as a return or if it has another 10g wire in the harness for ground (return). Chassis return for any high current 12V circuit is playing russian roulette. There are too many areas between various metal components in a vehicle that could cause resistance, heat, low voltage, lord knows what. Always best to run same gauge wire for "hot" and "ground".

Tomorrow I'm going to hook up a near depleted, AGM test battery to pin #7 and do some testing.........

You are totally correct! I will point out a few things about wire ampacity:

-Wire ampacity can be stated in regard to temperature rise (basically, the wire won't become unsafe and burn)

-Wire ampacity can be stated in regard to voltage drop.

So, you may find on the interwebs, many definitions of what 10AWG wire can handle (sounds like your truck has similar config as my Titan). I can find a chart that shows 12AWG could handle 30A! (this would be the chart that allows high temp rise of a conductor) And I can find a chart that would prefer 6AWG if low V drop is required.

Problem for 12VDC is we start with a fairly low voltage, and any V drop worsens it. With higher voltages, V drop is less of a concern.

The 30A fuse selected by our truck manufacturers

protects the wire and connectors. It does not guarantee we will have a reasonable V drop at 30A. It only

guarantees our truck won't burn down or suffer a failure at some point.

The Renogy wire charts assumes worst case scenario, a 20A Renogy will try it's damndest to maintain 20A at 14.7V output, meaning it

COULD pull as much as 323 watts overall (90% efficiency), as the input voltage drops (because 10AWG wire) the current will rise. At 13 VDC the current would only be about 24.8A, HOWEVER, if the 10AWG wire suffers a 2 V drop at 24.8A, we are now looking at 11 VDC and the Renogy will begin pulling 29.4A, and should we experience another 1 V drop the Renogy will begin pulling 32.3A at which point the fuse will open (theoretically) and charging will cease. The Renogy is capable of pulling ever higher currents until (I believe) 8V input.

However, I doubt a properly used/maintained AGM will cause a Renogy to work so hard.

I like your idea. If it were me, I would find a 30A @ 12VDC load and connect it to the 7 pin while the truck is running, I'd measure the V drop and current draw and determine if the truck could support the 20A Renogy.

Personally, I'd install a Renogy 20A and test to see if the OEM wiring is sufficient. Worst case, upgrade the wiring to the 7 pin. Or, add a separate wired circuit from a Tyco 75A relay (I use these in my truck for the lighting system and another for my AC inverter so both circuits aren't always powered)

I was going to run an AGM in the back of my truck and use a 20A Renogy to maintain it as I drove around, but I decided to get a Noco GB70 instead to keep me safe if I kill my main battery in the outback. I wouldn't want to torture an expensive/nice AGM with unconditioned charging. You definitely want a DC-DC charger to keep an AGM at peak condition.