Advocate I

Advocate I

Enthusiast III

Advocate I

Thanks mate - Ill start googling the Lowe's terms and seeing if I can match it up over here.It looks to me like hardboard. Lowe’s call it “brown wall panel”. Not very weather resistant though. No telling what they call it in your part of the world!

Advocate III

.Hi everyone!

The attached pic I found on a thread while reading through the site, however my google'ing skills are lacking for researching. If anyone can help with what the shelf material is that'd be fantastic! Im attempting to knock-up a similar setup on the side of my Ranger.

Cheers

View attachment 193935

Pioneer II

23055

Great Info. Thanks!For sealing the edges of plywood look for a thinned epoxy (viscosity of diesel) with a long cure time (cure time measured in hours, not minutes).

This is the stuff I like: Rot Doctor CPES

The challenge with plywood is that it has end grain on all four edges, and end grain is what soaks up moisture the best. And with moisture, you are looking at everything from liquid water (precipitation) to water vapor (atmospheric humidity). The wood will absorb any of it, and paint is not a good enough barrier for plywood in an exposed location.

One other detail about plywood, make sure you are choosing a plywood made with an exterior grade glue. Some plywood is intended only for interior use. The adhesive used between the layers is different for interior vs exterior plywoods. If you aren't sure, talk to the supplier.

Advocate III

.For sealing the edges of plywood look for a thinned epoxy (viscosity of diesel) with a long cure time (cure time measured in hours, not minutes).

This is the stuff I like: Rot Doctor CPES

The challenge with plywood is that it has end grain on all four edges, and end grain is what soaks up moisture the best. And with moisture, you are looking at everything from liquid water (precipitation) to water vapor (atmospheric humidity). The wood will absorb any of it, and paint is not a good enough barrier for plywood in an exposed location.

One other detail about plywood, make sure you are choosing a plywood made with an exterior grade glue. Some plywood is intended only for interior use. The adhesive used between the layers is different for interior vs exterior plywoods. If you aren't sure, talk to the supplier.

Advocate I

Agree - I tried looking for the post again so I could ask the POC, nil joy with that so thought I'd post..

Why not ask the person who posted it?

This looks like a piece of plywood painted black, with aluminum angle trim applied via screws into the edge side of the ply and through bolts for the hanger rings. Birch ply will give the smoothest surface.

"Brown wall panel" is masonite (hardboard), usually only 3mm 0r 6mm thickness. It is usually available as regular (generally one side finished, the other rough) or tempered, which has a harder more impervious surface.

If fabbing up your own, I'd use 12mm or 18mm birch ply, primed with an exterior primer and painted with a good exterior paint. Be sure to fill all edge voids with a good caulk before finishing. I would paint the underside as well, and would attach a couple rubber bumpers along the back edge to protect your vehicle.

If you like a clear natural look, simply apply a couple coats of Polycrylic, sanded lightly in between coats. Provides a very smooth, water resistant, clear finish. Plenty durable for outside use if only using the table intermittently. It's what I use on my van floor and side cupboards and it has held up extremely well for years.

.

Advocate III

.Agree - I tried looking for the post again so I could ask the POC, nil joy with that so thought I'd post.

Thanks for info, Im heading to the hardware store today so I'll add the exterior paint and primer to the list.

Advocate I

Wow that Red Doc CPES looks excellent! Thanks for the hot tipsFor sealing the edges of plywood look for a thinned epoxy (viscosity of diesel) with a long cure time (cure time measured in hours, not minutes).

This is the stuff I like: Rot Doctor CPES

The challenge with plywood is that it has end grain on all four edges, and end grain is what soaks up moisture the best. And with moisture, you are looking at everything from liquid water (precipitation) to water vapor (atmospheric humidity). The wood will absorb any of it, and paint is not a good enough barrier for plywood in an exposed location.

One other detail about plywood, make sure you are choosing a plywood made with an exterior grade glue. Some plywood is intended only for interior use. The adhesive used between the layers is different for interior vs exterior plywoods. If you aren't sure, talk to the supplier.

Advocate I

Will post once she's knocked up. Hopefully Ill have time and a finished product before heading up to Fraser Island in a week..

Cool, hope it works the way you want. Post up the results!

I've been thinking of making a locking holder for my traction boards to attach to the side of my vehicle when back country (perhaps removable for the highway), which will double as flip down work surface/table area. It's an idea I am boldly stealing from 4xoverland as seen on a Ronny Dalh's Modified vid years ago (29 min mark).

I'm always tinkering in camp with some kind of project and having another work surface is always handy, especially if away from the trailer.

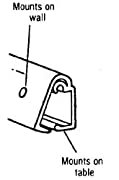

I also have a couple sets of 30" interlocking table rails I'm going to play with for removable table/work surfaces. The image there is terrible, though the cross section looks like this, for anyone interested:

View attachment 193973

As it shows, one length mounts to the surface where you want a table, the other mounts to the edge of whatever you're using as table. Then you can lift the table up to remove, reverse to put back. I'm sure I'd add adjustable leg or two to further support for heavier loads, or have cables with hooks that go up to the van's gutter.

.

y'all should have some good plywood to work with. for whatever reason, Australia has the BEST wood working tools. i use Vicmarc tools for turning and they're made in Australia and Kelton Industries makes an awesome bowl coring system in NZ. some of the really good wood finishes also come from Australia. i'd do a trip down there just to check out your hardware and lumber storesIm heading to the hardware store today

Pioneer II

23055

Good Luck!Agree - I tried looking for the post again so I could ask the POC, nil joy with that so thought I'd post.

Thanks for info, Im heading to the hardware store today so I'll add the exterior paint and primer to the list.

Advocate I

Our hardware stores have an almost cult like following down here. Everyone knows about a trip to Bunnings on a Saturday morning for a snag in bread w/ sauce and oniony'all should have some good plywood to work with. for whatever reason, Australia has the BEST wood working tools. i use Vicmarc tools for turning and they're made in Australia and Kelton Industries makes an awesome bowl coring system in NZ. some of the really good wood finishes also come from Australia. i'd do a trip down there just to check out your hardware and lumber stores