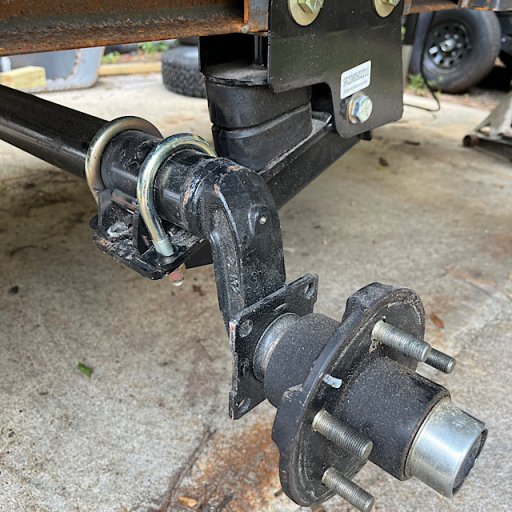

So I am thinking that I mat try to use the torsion axles that I have sitting around... at least for now. I am not sure how they will hold up and my straight axle I have is currently under a trailer I use to move my TJs hardtop around in the summer. This will save me some hassle ( short term at least) of building control arms for an independent coil sprung suspension. It will also allow me to see how the weight of mt trailer reacts to a 2000lb "spring" which fully loaded the trailer may be close to that weight ( although I am thinking closer to 1500 lbs).

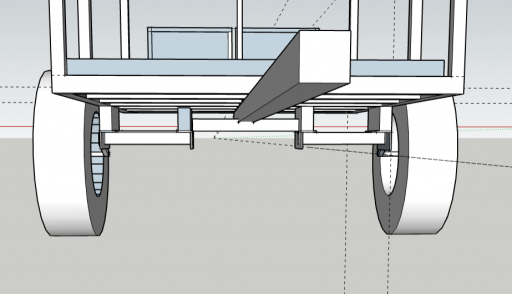

The downside to this is the torsion axles sit low and are not as easy to "lift". So I am thinking of basically making a brace to drop the mounting points lower and provide the extra height needed to get the trailer sitting roughly where I want it. Here is what I have come up with.....I'm thinking that my axle drop for torsion axles may just end up being 2x2 all the way across/through and 6x2 risers with a plate for the torsion axles to sit on... if anyone see any issues, weak points, cause for concern I'm all ears. Again I am kinda just using parts I have laying around already to build this thing without trying to spend a whole lot of money on it ( which I know can sometimes bite me in the ass).

View attachment 252681