I'm not sure what welding cable the others are running, I have been making my own battery cables out of it for literally decades. What I like about it is, its a finer strand of wire and has a higher copper content than most battery cable's. As for oil/heat resistant, I have never seen an issue with it, ever. That's not only on my projects.

I have had oil dripping over my cables (I hate oil leaks). Not for years and years but enough to say it holds up as well as anything else I've had oil on. Most of my vehicles run dual batteries, which puts my cables well into the hot soak area in my engine compartment. Never had the insulation on mine or others I've seen get brittle or crack.

It is more flexible. You need to make sure its fastened correctly. It will sag if not. maybe "others" let it sag onto or real close to exhaust? I also run it in a

braided sheath for extra abrasion protection. If I was going near exhaust I would run the

high temp shielding. In the past, I used

split loom and recently changed over due to the split loom gives it much bigger diameter. The sheath protectors work so much better.

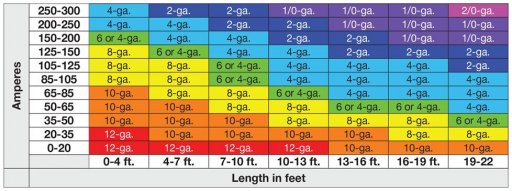

Your question on size, I would be running double 00. Run the spec on your winch for max draw. You may get away with single 0. I use single on my 12k winches and all my battery cables. I would have no issue running single to the rear for the 12k.

Get a hammer staking tool and some eyelets from the welding shop or from someone who sells quality, heavy eyelets and insulate the ends with

dual wall shrink tubing. I prefer the "adhesive" type. It has a resin inside that not only seals but add a bit of rigidity to it.