Well, 22 September fell through for us, so we had to postpone to the 10th of this month.

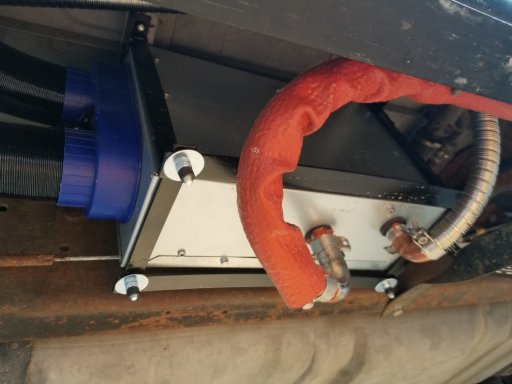

A.J.'s swapped out heavier springs, air bags, redesigned radius arm mounts, and updated (later F350-style) track bar.

Since we were mid-trip, Art and the crew pushed hard to get us in and out in 5 hours. Worked through lunch, even.

The radius arm mounts are really beefy and lower the pivot points 2" for better caster figures. This is something I discussed with Art after our initial build. He welcomes and uses feedback like that.

The change in the track bar reduces bump steer, better roll center, and seems stronger (less severe angle).

The stiffer springs and airbags made a huge difference. Earlier in this thread I said the van weighed 8500# all in. Well, there's been some changes since then. Loaded, both of us, full water and fuel, it's sitting at 9150. 4300 front/4850 rear. The front was "squishy", to say the least.

Results?

First immediate thing is it sets a little over an inch higher in the front (haven't measured it).

Does NOT bottom out on the bump stops now (it was living there before).

I can comfortably go around corners 5 MPH higher than they are posted (before it was no more than the posted speed, and hang on at that).

One hand, relaxed steering at the speed limit on two lane backroads (had to constantly work at it before).

I have been wrangling trying to get a sway bar to work with the van frame/pick up axle. Don't need it now.

So, was the initial build bad? I don't think so. I just kept adding weight and exceeded the spring rate. I put changing the design geometry of the radius arms and track bar down to product improvement based on customer feedback. Customer satisfaction and support is critical to Art, and he treated me more than fair on this upgrade.

I was going to build a set of bumpers, with a winch mount front and dual swing arms in the back, but my welding and fabrication is limited to steel. Given the current weight concerns, looks like I'm going to have to pony up for Aluminess (ouch).