Maddog74

Rank II

Enthusiast III

Enthusiast III

Member III

Enthusiast III

Enthusiast III

Enthusiast III

While your building your Truck Rack, here is one that I made for Pops on his Chevy. It's full size Rack, 4x6, with offroad lights and power plugs on the post holding up the rack. Hope if give you some more ideas on building your rack. 2017 Silverado D-Cabtesting out a 3D printed dimple die... 2" hole in 16 gauge mild steel

I have a few idea for the bed rack where this may come handy.View attachment 159760View attachment 159759

Enthusiast III

Quick update...looks like this is going to die the slow death, or at least long term life support until I can get a tube bender bought. I was hoping it would have been finished weeks ago, but life has gotten in the way.

Enthusiast III

Advocate III

20990

Member III

16986

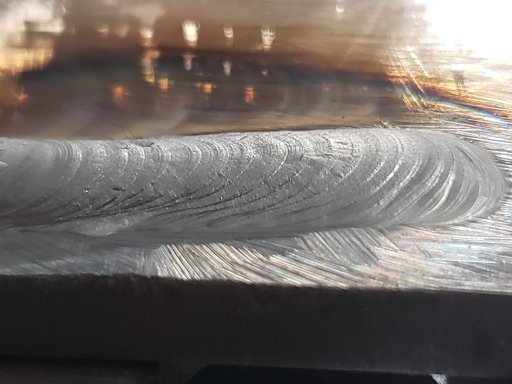

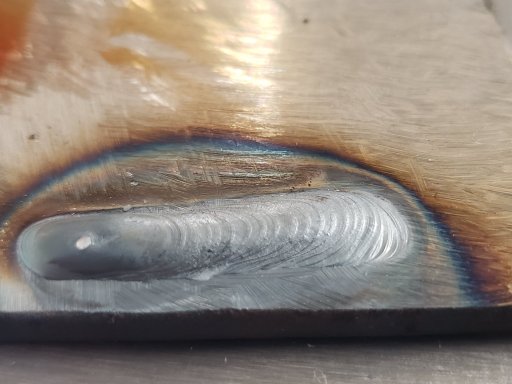

It didn't look like very much penetration to me. I'm not familiar with tig but with arch welder you can see it penetrating as you weld. I bought a flux welder to play with one of these days. I like the idea of being able to weld sheet metal..I’m glad to see you are still going to be building this.

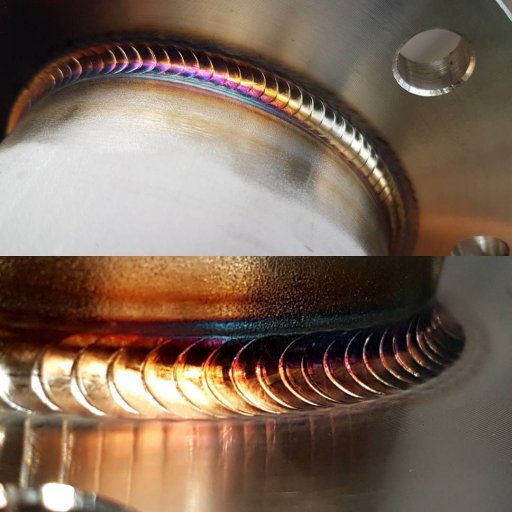

I don’t know much about TIG, but it looks like you are moving the toungsten too fast. The stack of

Coins should be a rainbow color.

Advocate III

20990

Yes no penetration.... the color told me that alone... also the puddle tells that he’s not welding with his wrist and the power settings are low...It didn't look like very much penetration to me. I'm not familiar with tig but with arch welder you can see it penetrating as you weld. I bought a flux welder to play with one of these days. I like the idea of being able to weld sheet metal..

In the past I have only used acetylene torch and bailing wire or flux copper wire for sheet metal. Flux seems simple and will weld 1/4" steel nicely. I like because no gas is needed and any 110v outlet will do. You could probably use a car battery with inverter for power.

Enthusiast III

Advocate III

20990

Enthusiast III

I understand the frustration.... I’ve done the same thing multiple times.

Enthusiast III

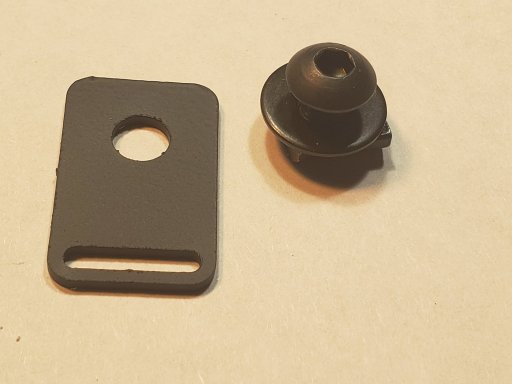

redesigned this bracket, using the knowledge learned by the above mistake, and learning better ways of modeling a sheet metal part in CAD. I think I am gonna 3D print a slice of the bracket for a test fit.Got the bed brackets bent up today.... Discovered a few minor adjustments that will likely get done at final assembly.

View attachment 122343

View attachment 122344

View attachment 122342

I may need to extend the bolt slots a bit.

View attachment 122341

Top of the bracket is a hair longer than I would like, once the bed bars are welded on I may trim this a bit to keep it flush with the bed side.

Enthusiast III

Enthusiast III

Advocate III

20990

Enthusiast III

Still working on a design for that.. planning a on a table with a 4'x4' cut area thinking 2x2 tube for the base table 3060 extrusion for the gantry 25mm linear rail s with 20mm ball screws possible downdraft over a water tablePrototyping with a 3D printer is a very good idea... how’s the CNC table coming along?

Enthusiast III