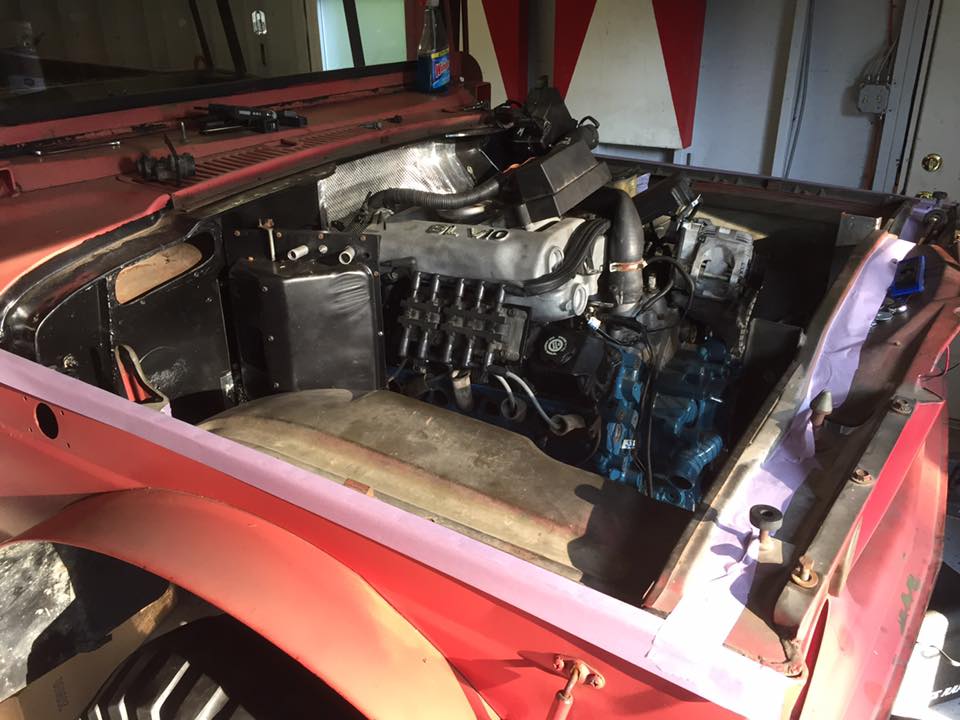

So today, the big milestone happened! The engine was turned on!!!

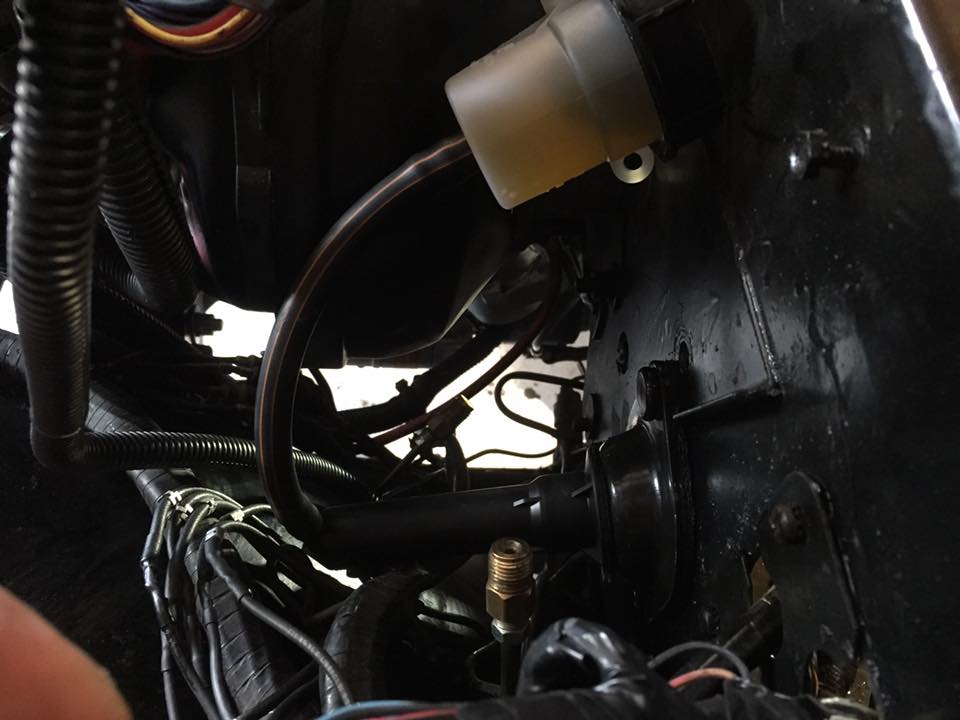

After a minor problem with fuel pressure, we got it to run!!! It worked 95% of the way it's supposed to. Cylinder 4 doesn't appear to be igniting. We did a compression test and spark test and it all looks ok. I think the injector is dumping fuel into the cylinder. I'll order a new one and hopefully that will fix it. Other than that, the engine works!!!!!!

__________________

After a minor problem with fuel pressure, we got it to run!!! It worked 95% of the way it's supposed to. Cylinder 4 doesn't appear to be igniting. We did a compression test and spark test and it all looks ok. I think the injector is dumping fuel into the cylinder. I'll order a new one and hopefully that will fix it. Other than that, the engine works!!!!!!

__________________