I am looking to build a roof platform for at least one of my vehicles, but maybe both. I have been thinking about how heavy the material needs to be to hold what I would likely put up on the roof, which usually isn't a whole lot ( a couple of totes full of camping gear, maybe fire wood, a couple of small kayaks....).

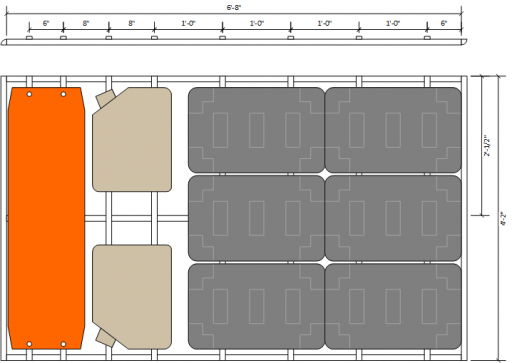

I was thinking about a 3x1x0.125 or 2x1x0.125 to make an outer ring and then maybe 1x1x0.100 for the cross rails to save weight but I could go heavier on any of it.

I am not an engineer by any means, but I can weld. My understanding is that a 1x1x0.125 at a length of 4' would have a deflection of approximately 1" (roughly) with a 1000lb load, which I would never have that much weight up top. I figure I would likely put around 200lbs up top at most, however I want to build this to be capable of a 500lb load to be on the safe side.

I have access to nearly any size of material but I can only weld steel, and would like to keep the cost and weight as low as possible.

Any ideas or suggestions would be great!

Thank you

I was thinking about a 3x1x0.125 or 2x1x0.125 to make an outer ring and then maybe 1x1x0.100 for the cross rails to save weight but I could go heavier on any of it.

I am not an engineer by any means, but I can weld. My understanding is that a 1x1x0.125 at a length of 4' would have a deflection of approximately 1" (roughly) with a 1000lb load, which I would never have that much weight up top. I figure I would likely put around 200lbs up top at most, however I want to build this to be capable of a 500lb load to be on the safe side.

I have access to nearly any size of material but I can only weld steel, and would like to keep the cost and weight as low as possible.

Any ideas or suggestions would be great!

Thank you