Think light tubing, not pipe not sure on the gauge but 1/8" wall is wayy heavier than what you need on an LJ. While I agree, no one builds what you want/need check out what they use in manufactured racks.I am looking to build a roof platform for at least one of my vehicles, but maybe both. I have been thinking about how heavy the material needs to be to hold what I would likely put up on the roof, which usually isn't a whole lot ( a couple of totes full of camping gear, maybe fire wood, a couple of small kayaks....).

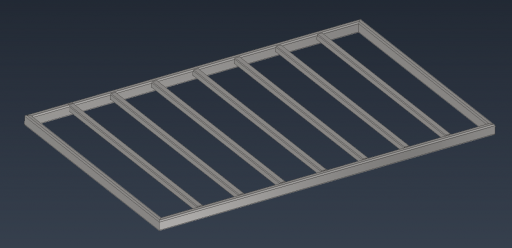

I was thinking about a 3x1x0.125 or 2x1x0.125 to make an outer ring and then maybe 1x1x0.100 for the cross rails to save weight but I could go heavier on any of it.

I am not an engineer by any means, but I can weld. My understanding is that a 1x1x0.125 at a length of 4' would have a deflection of approximately 1" (roughly) with a 1000lb load, which I would never have that much weight up top. I figure I would likely put around 200lbs up top at most, however I want to build this to be capable of a 500lb load to be on the safe side.

I have access to nearly any size of material but I can only weld steel, and would like to keep the cost and weight as low as possible.

Any ideas or suggestions would be great!

Thank you

The one thing every home fabricator does is build it double or triple heavier than they need. Compare what the manufactured racks are built with.

I ran lumber yards and we built the overhead racks for our pickups to haul 20' rebar and 16' lumber, we used light wieght 1.5" by 1.5"" crossmembers, 72" long and 2" x 3" x 1/8" wall tube for the left and right sides, and the 6 uprights. We cut 12' lengths, 8' over the box, 4' cantilever over the cab and we would load up to 60 pieces of 20' rebar. 4' overhang at each end. Crossbars were lighter and 1.5" x 1.5", 4' on center. 30 sticks tied to the right side, 230#, 30 tied to left side, 230#. Plus a bunch of 2x4 and 2x6 16' lengths in the middle. Never an issue.

We overlanders really over build.

Last edited: