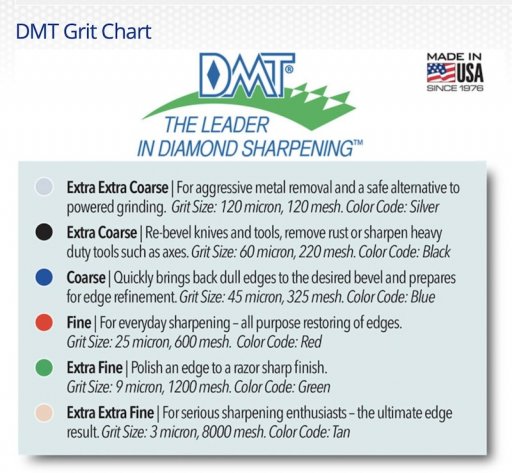

Diamond plates (industrial sapphire). Modern knife steels aren't your Grand Pappy's old high carbon steels anymore.Yep, the S30V sure is hard to dull and hard to sharpen.

What sharpening setup do you use?

Smith's setup that I purchased in the '90s seems to work good for mine, but I'm wondering if something else out there is easier and faster.

View attachment 271138

S30v,S35vn,Manacut,Elmax,,S90V,S110v, M3,M4,M390,CPM D2 any of the powder metallurgy or high speed tool steels, you're not going to get it done with natural stones or even man made like Norton Fine India or Crystolon. Anything that hardens into the 60 Rockwell range is going to pretty much demand diamond plates or a loooooooong time and a very steady hand(or a guide system).

8cr13mov,9cr14mov,10cr15mov,AEBl,154CM,14c28n,VG10 can be managed on traditional "stones" and are adequate steel for most uses (pocket knife) but that is still dependent on who does the heat treat. Spyderco does a great job with 8cr and VG10(and heat treating in general), other brands 8cr is just junk.

People are quick to recommend the latest "super steels" but if the end user isn't prepared to deal with them when they need sharpening, they ultimately are not well served with them. If I was picking one folding knife steel that demonstrated good properties relative to usability (ease of sharpening, edge retention,high chrome content/stainless-ness,toughness) coupled with affordability for someone who is not prepared for super-steels, it would probably be Sandvik 14c28n .