astroflashjones

Rank V

Advocate I

Advocate I

Steward I

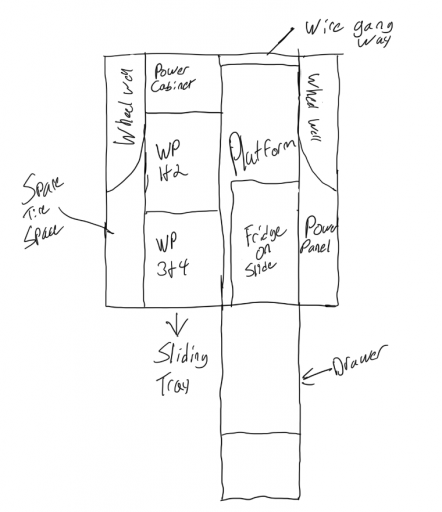

Likewise. I'm gonna go with plywood. Thinking 2 drawers for gear on one side, and a fridge pull out with another sliding drawer underneath for the Coleman stove, and another under that for a collapsible sink. Trying to decide now whether I want an inline pump for the water supply, of if I'll just let gravity do all the work. Good luck with your build.Great, I'm interested to see what you do! Trying to decide what I'll be using for materials at this point.Thanks. Yes I will be building my own. Working on plans right now.

Trail Blazer I

15310

You as well! I'm pretty sure Plywood will be most of it. I may use PVC where I can for low weight bearing surfaces. Here's the rough mock. I will be iterating on this as I think of things and getting proper measurements. I'll have a tray for my Wolfpack boxes then an actual drawer on the side.Likewise. I'm gonna go with plywood. Thinking 2 drawers for gear on one side, and a fridge pull out with another sliding drawer underneath for the Coleman stove, and another under that for a collapsible sink. Trying to decide now whether I want an inline pump for the water supply, of if I'll just let gravity do all the work. Good luck with your build.

Steward I

I like it. Looks good. I would also like to put in a small power supply, and a switch for the light on my rear hatch. Here's what I have so far. Like yours, this is just a rough draft, and things will probably change a bit as the build progresses. As far as weight reduction, I have seen some, cut sections out of the sides and base. I will implement this where I can.You as well! I'm pretty sure Plywood will be most of it. I may use PVC where I can for low weight bearing surfaces. Here's the rough mock. I will be iterating on this as I think of things and getting proper measurements. I'll have a tray for my Wolfpack boxes then an actual drawer on the side.Likewise. I'm gonna go with plywood. Thinking 2 drawers for gear on one side, and a fridge pull out with another sliding drawer underneath for the Coleman stove, and another under that for a collapsible sink. Trying to decide now whether I want an inline pump for the water supply, of if I'll just let gravity do all the work. Good luck with your build.

View attachment 226659

Member II

30139

Pathfinder I

Love them! they hold up to serious use. This is my second setHow do you like those KM3s?

Trail Blazer I

15310

No issues with cupping or anything like that?Love them! they hold up to serious use. This is my second set

Pathfinder I

Keep up on the rotation and it seems ok. I had a few issues on the first set, but I went way too long on rotatingNo issues with cupping or anything like that?

Member III

17264

Trail Mechanic III

29878

Love the Ka BarInstalled molle panel on my 2020 Tundra. Not as easy as Rago Fabrication youtube install video shows. Bolts closest to the seat were almost impossible to get to.

View attachment 226764View attachment 226766

Member II

20275

Trail Blazer I

15310

I feel you. My Taco panels were hard too. Especially since I have large hands. But I was able to get them in with a little patience. Note to anyone out there for these, if you have a friend with small/smaller hands try to get them to help.Installed molle panel on my 2020 Tundra. Not as easy as Rago Fabrication youtube install video shows. Bolts closest to the seat were almost impossible to get to.

Member II

30139

Cupping is normally a shock issue. (could be a few other things) If you've ever seen a tire hopping up and down on someone's car as they cruise by, that's the problem. LOLNo issues with cupping or anything like that?

Member II

30139

That rear window is all business. Dammit man. LOLI feel you. My Taco panels were hard too. Especially since I have large hands. But I was able to get them in with a little patience. Note to anyone out there for these, if you have a friend with small/smaller hands try to get them to help.

View attachment 226806View attachment 226807View attachment 226808

Trail Blazer I

15310

That's fair. My MTs currently were ran under pressure for a bit too long and I can feel it now. Damn Up and Down temps made it hard to keep at Optimal pressure.Cupping is normally a shock issue. (could be a few other things) If you've ever seen a tire hopping up and down on someone's car as they cruise by, that's the problem. LOL

Zim

Trail Blazer I

15310

Thanks Zim! I love the panel, but again it was a pain to put in myself, not to mention I had just strained 3 dominant shoulder muscles.That rear window is all business. Dammit man. LOL

Zim

Member II

30139

Ouch. I started making a temp "headache" rack and it's too big to put on the bench. So, like a idiot, went to the gym in the morning, worked on the concrete most of the day, and in the evening can't walk. LMAO. Hate getting old but just have to deal with it. Hands are sore almost every day.Thanks Zim! I love the panel, but again it was a pain to put in myself, not to mention I had just strained 3 dominant shoulder muscles.

Off-Road Ranger I

29302

That looks amazing! Nice job Zim! WOW!I'm done. I'm sure y'all glad too. LMAO. One of the hardest things I've ever made because AWKWARD! LOL

So now on to the headache rack. Will be lots easier than this SOB. (disclaimer; I did not make the brush guard, just the bumper in 3 pcs.)

Winch is on the way.

Zim

View attachment 226706

Member II

30139

Thanks Buddy. I appreciate all your support. Now on to bigger and better things, like rest.That looks amazing! Nice job Zim! WOW!

Trail Blazer III

28559