Member III

Its not that tough to do, really. The bigger thing that the job a HUGE pain was not having the right bearing presses, race presses, seal tools, bearing pullers, etc. The measurements are trivial to do, reading the gear mesh pattern and trying to figure out what to do with it was a challenge, but overall its still easier than a lot of what we do for some of our space qualified motors/gearboxes.That's tough work and I know some serious ASE guys that would not touch it....Nice work. Did that one have a pinion crush sleave or naww.?

Zim

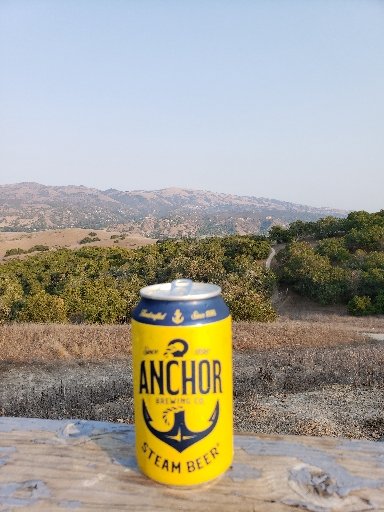

The other side of course, were the physical demands of this job, and that was VERY challenging.