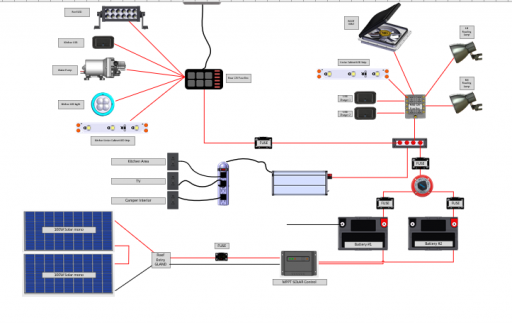

Wiring is something i take seriously as it is likely the main thing that can burn a rig to the ground if done incorrectly and a short occurs in a unprotected circuit in a worse case scenario. on the annoying level is when a connection fails or is intermitant causing outages or failed equipment. chasing elecrical gremlins out in teh woods can be a pain in the behind. Good quality connectors are critical, the cheap crimp on wire connectors can corrode, are made of substandard materials that will not hold a crimp. just as importantly is using the correct crimping tool for the connector of choice. Deutch connectors, butt splices and anderson plugs all require a different profile on the crimper, use the wrong one and the wire may be loose or the connector damaged. for standard crimp on connectors, I like the ones with heat shrink with heat activated sealant. for most connections I have switched to the deutch DT style as they are waterproof and disconnectable. Big debate on solder connections for mobile use, therory is solder wicks into the stranded wire creating a hard area where constant flexing can cause the strands to fail over time, and todays crimped and sealed connections do as good or better of a job. Above all make sure to protect all wiring where it goes thru a hole or over a sharp edge, use grommets, or sections of rubber hose to protect. Zip ties are cheap and a great way to secure wires out of harms way. found some ties that have built in 'Christmas Trees' that allow them to be inserted into a 1/4" hole and then around a cable bundle.

I agree that HF stuff comes from the same place as most anything on Amazon just at a cheaper cost and better ability to return. I do use them for some items with low risk factor, have been happy with the Icon line from them, but avoid anything hydraulic asI have had really bad luck in that department. Just had a 9 dollar angle grinder of thiers die after only 8 years of hard use...not a bad investment on that one.