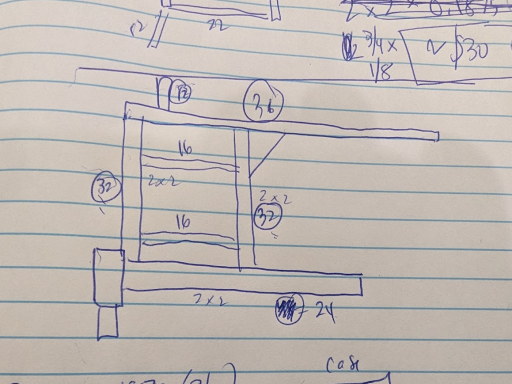

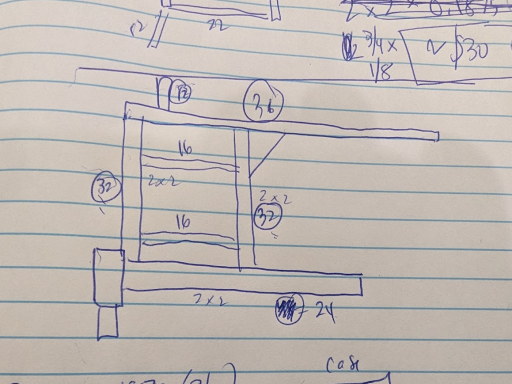

I'm looking to build a swing-out carrier for half of the rear of my rig. Tire is door-mounted so this won't carry the tire. The plan is to have it about 2' long (off the left end of the bumper frame) with a 2x2 square tube bottom piece and two 2x2 vertical pieces. The verticals will mount a 24" x 16" chuck box (probably some kind of pelican case or similar), and a the top of the verticals I'm basically going to have a horizontal bar that goes across the rear window right above the spare (about 36" long total). See pic below. The upper crossbar will have a gear shelf on it, to hold a 5-10lb propane tank, maybe a cooler, and other fairly lighweight stuff - total less than 100lbs.

See my sketch below

Anyhow, for a tire swing-out I'd definitely want to go with 3/16" or maybe 1/4" tubing, but this is a small rig (2-door Raider/Montero) and keeping things as light as possible is always a goal. So thinking about building this in 1/8", with a few gussets in key places for extra support I just measured the tubing on my 1000lb engine hoist and it's 1/8" so figure that's probably strong enough, since this will only hold a fraction of that weight.

So any thoughts on going with the lighter-weight tubing to save weight (and money, for that matter)? I'm leaning that direction but a sanity check is always good.

general design, minus the gussets, etc. Anything heavy would be on the left side, basically as close to the pivot as possible. The spare tire is in the open area on the right, if you can picture it. The circled numbers are the piece lengths in inches.

back of the rig in question. Spare tire is now moved about 2" to the right, but more or less the same. The upper bar will basically cross over where that antenna platform is in the photo (it has since been removed).

The two uprights will basically go directly on either side of the RAIDER / door latch housing

See my sketch below

Anyhow, for a tire swing-out I'd definitely want to go with 3/16" or maybe 1/4" tubing, but this is a small rig (2-door Raider/Montero) and keeping things as light as possible is always a goal. So thinking about building this in 1/8", with a few gussets in key places for extra support I just measured the tubing on my 1000lb engine hoist and it's 1/8" so figure that's probably strong enough, since this will only hold a fraction of that weight.

So any thoughts on going with the lighter-weight tubing to save weight (and money, for that matter)? I'm leaning that direction but a sanity check is always good.

general design, minus the gussets, etc. Anything heavy would be on the left side, basically as close to the pivot as possible. The spare tire is in the open area on the right, if you can picture it. The circled numbers are the piece lengths in inches.

back of the rig in question. Spare tire is now moved about 2" to the right, but more or less the same. The upper bar will basically cross over where that antenna platform is in the photo (it has since been removed).

The two uprights will basically go directly on either side of the RAIDER / door latch housing