Benefactor

Here's another excerpt from my training manual I've been working on. One day it will be ready as a handout for classes:)

Before I get into talking about shackles, I want to define and explain the abbreviations you'll see below.

WLL - Working Load Limit is what you will typically see stamped into the body of the shackle. SWL (Safe Working Limit) is also used, though not as often. What the WLL means is that a piece of equipment can be used all day up to the rating and not have an issue with deforming or breaking. If that limit is exceeded, the shackle should be inspected by a professional, and possibly placed out of service.

MBS - Minimum Breaking Strength is the minimum amount of force a piece of equipment can endure before breaking to the point of complete failure. For a typical 3/4" shackle with a WLL of 4 ¾ tons, that's 23.75 tons!

SF - Safety Factor is how much additional strength is available in a piece of equipment beyond the intended load. This is typically shown as a ratio of additional strength to the load. As most of our recovery gear comes from the lifting industry, our shackles must have at least a 5:1 safety factor since they are used in overhead applications. Equipment involving human life can be 10:1 or higher.

So how do all these relate to each other? Well, you start with the MBS of a shackle and use this formula to determine it's WLL. For the example, I'll again use a typical 3/4" shackle.

WLL=MBS/SF

In tons:

4¾=23.75/5

In pounds:

9,500= 47,500/5

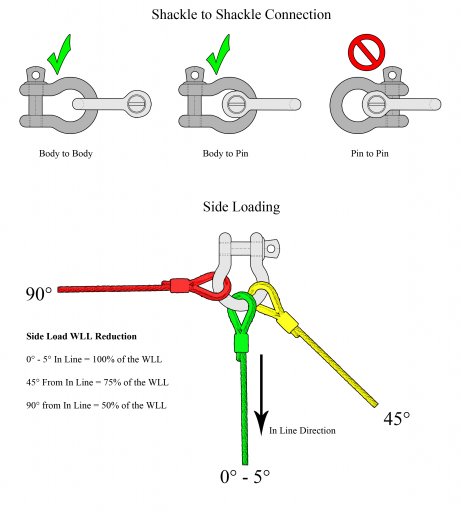

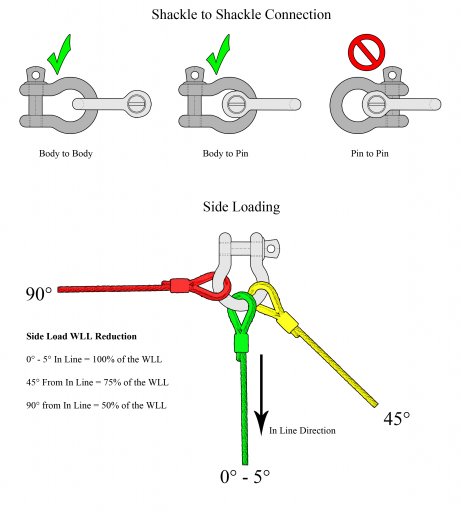

Bow Shackles with a ¾” Body and a 4 ¾ Ton WLL are the standard. Safety factor should be 5:1 minimum. Van Beest “Green Pin” & Crosby shackles are individually tested with a safety factor of 6:1. When attaching eye loops of a strap, always rig them to the bow part of the shackle. Use the screw pin for your hook or thimble. Never rig a line or anything that will run over the pin. It can either spin it out, or over tighten it. If it’s a steel cable, it can actually grind the surface away causing (at least) the pin to be removed from service, if not the entire shackle.

Loads should be placed along the centerline of the shackle. A bow shackle can have up to a 120° load (say, using a bridle), so long as each leg is equally loaded. Never side load a shackle. Within 5° of centerline, 100% WLL is maintained. At 45°, the WLL is reduced to 70%. At 90° it’s 50% (see illustration below). Beyond the reduction of WLL, a side load can permanently distort the body of the shackle to the point of not being able to remove the pin. Never use a metal shackle to connect two Recovery Straps. It can become a flying projectile if a strap breaks. Due to the extreme loads placed on the pin, always remember to back it off by ½ a turn after it’s tight. This will help prevent it from jamming in place and make it easier to unscrew.

Using Shackles

Soft Shackles are a different approach to secure attachment points. They are made from Dyneema (or AmSteel Blue, SK-75) and should have all safety ratings information on a tag. They have an adjustable opening and close with a cinch, or choker in principle. The more load applied around the loop the harder it is for the knot to pull through it.

One main advantage is that they can fit where a Bow Shackle simply cannot. A skinny slot in a slider, around a roof rack bar, or over a hitch pin inside the receiver hitch are all places a shackle may not fit. Another advantage is the material is very lightweight and soft instead of heavy steel, just waiting to go flying through the air. The MBS should be at least 18,000 lbs. for 3/8" line.

Before I get into talking about shackles, I want to define and explain the abbreviations you'll see below.

WLL - Working Load Limit is what you will typically see stamped into the body of the shackle. SWL (Safe Working Limit) is also used, though not as often. What the WLL means is that a piece of equipment can be used all day up to the rating and not have an issue with deforming or breaking. If that limit is exceeded, the shackle should be inspected by a professional, and possibly placed out of service.

MBS - Minimum Breaking Strength is the minimum amount of force a piece of equipment can endure before breaking to the point of complete failure. For a typical 3/4" shackle with a WLL of 4 ¾ tons, that's 23.75 tons!

SF - Safety Factor is how much additional strength is available in a piece of equipment beyond the intended load. This is typically shown as a ratio of additional strength to the load. As most of our recovery gear comes from the lifting industry, our shackles must have at least a 5:1 safety factor since they are used in overhead applications. Equipment involving human life can be 10:1 or higher.

So how do all these relate to each other? Well, you start with the MBS of a shackle and use this formula to determine it's WLL. For the example, I'll again use a typical 3/4" shackle.

WLL=MBS/SF

In tons:

4¾=23.75/5

In pounds:

9,500= 47,500/5

Bow Shackles with a ¾” Body and a 4 ¾ Ton WLL are the standard. Safety factor should be 5:1 minimum. Van Beest “Green Pin” & Crosby shackles are individually tested with a safety factor of 6:1. When attaching eye loops of a strap, always rig them to the bow part of the shackle. Use the screw pin for your hook or thimble. Never rig a line or anything that will run over the pin. It can either spin it out, or over tighten it. If it’s a steel cable, it can actually grind the surface away causing (at least) the pin to be removed from service, if not the entire shackle.

Loads should be placed along the centerline of the shackle. A bow shackle can have up to a 120° load (say, using a bridle), so long as each leg is equally loaded. Never side load a shackle. Within 5° of centerline, 100% WLL is maintained. At 45°, the WLL is reduced to 70%. At 90° it’s 50% (see illustration below). Beyond the reduction of WLL, a side load can permanently distort the body of the shackle to the point of not being able to remove the pin. Never use a metal shackle to connect two Recovery Straps. It can become a flying projectile if a strap breaks. Due to the extreme loads placed on the pin, always remember to back it off by ½ a turn after it’s tight. This will help prevent it from jamming in place and make it easier to unscrew.

Using Shackles

Soft Shackles are a different approach to secure attachment points. They are made from Dyneema (or AmSteel Blue, SK-75) and should have all safety ratings information on a tag. They have an adjustable opening and close with a cinch, or choker in principle. The more load applied around the loop the harder it is for the knot to pull through it.

One main advantage is that they can fit where a Bow Shackle simply cannot. A skinny slot in a slider, around a roof rack bar, or over a hitch pin inside the receiver hitch are all places a shackle may not fit. Another advantage is the material is very lightweight and soft instead of heavy steel, just waiting to go flying through the air. The MBS should be at least 18,000 lbs. for 3/8" line.