Explorer I

- 3,680

- First Name

- Brian

- Last Name

- McGahuey

- Member #

-

23711

- Ham/GMRS Callsign

- GMRS WRMV941

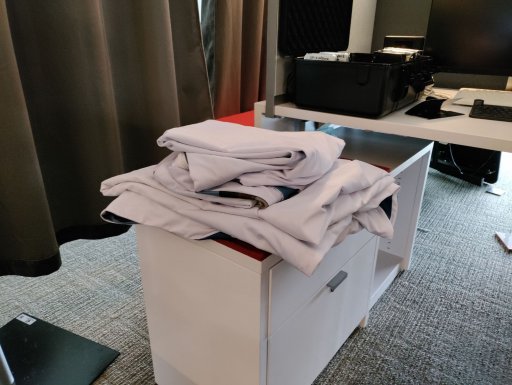

Only had one day this weekend, but now she's ready for paint!

Explorer I

23711

Explorer I

23711

Explorer I

23711

Explorer I

23711

Explorer I

23711

Thanks! I'm very pleased with how it's turned out. I think I'm going to come up with a different solution for mounting the stove box. I think I need to use some sort of bracket that brings the vertical strut channel closer to the body of the trailer. On top of that, when the axle get's moved next month, I don't think I'm going to be able to mount the bottom support where it currently is, so I'm going to have to look at how to solve that.Very cool! Nice job reaver.

** Also... go Milwaukee!

Explorer I

23711

I'm sure I could, but I'm trying to avoid bolting things directly to the wall if I can. That opens up more possibilities of water ingress, which I'm trying to avoid if I can. I can design a bracket that bolts to the frame, brings the strut channel up and out, and bolt it to that. I'm not going to do anything until after the axle gets moved though, since that will determine where it needs to go.Any reason you can't just bolt it directly to the main wall? Using enough bolts and fender washers maybe?

Explorer I

23711

Explorer I

23711

Thanks man! It's going to be a work in progress for quite some time. There's lots of tweaks that are going to take place, and I'm sure I'll think of more, the more I use it.Yay!! Very cool. Very jealous.

Creator III

20143

Explorer I

23711

Haha! That's how the box is held onto the floor. Grade 5 bolts to the frame of the trailer.Awesome Job! I built a trailer last year but went with cargo and RTT, I should have gone Square drop... BUT, the one thing I did do right was make the whole thing bolt to the frame, so I could unbolt it and start over LOL (my wife would kill me)

Explorer I

23711

Explorer I

23711

Explorer I

23711

Explorer I

23711

Explorer I

23711

Explorer I

23711