Explorer I

- 3,680

- First Name

- Brian

- Last Name

- McGahuey

- Member #

-

23711

- Ham/GMRS Callsign

- GMRS WRMV941

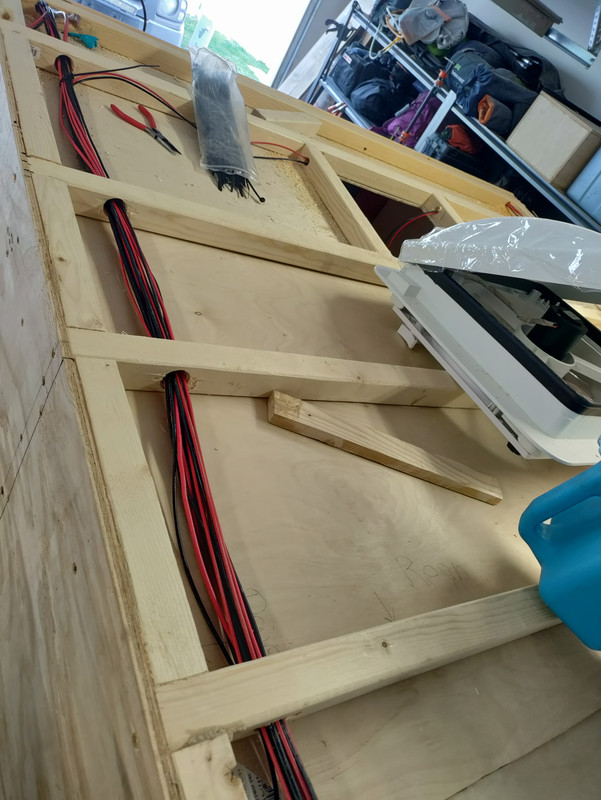

Had another great day working on the trailer today. Got the floor fully pmf'd, and flipped back over!

Using Pl premium adhesive, we attached the walls at the base, and screwed them into the 2x4s along the edge of the floor.

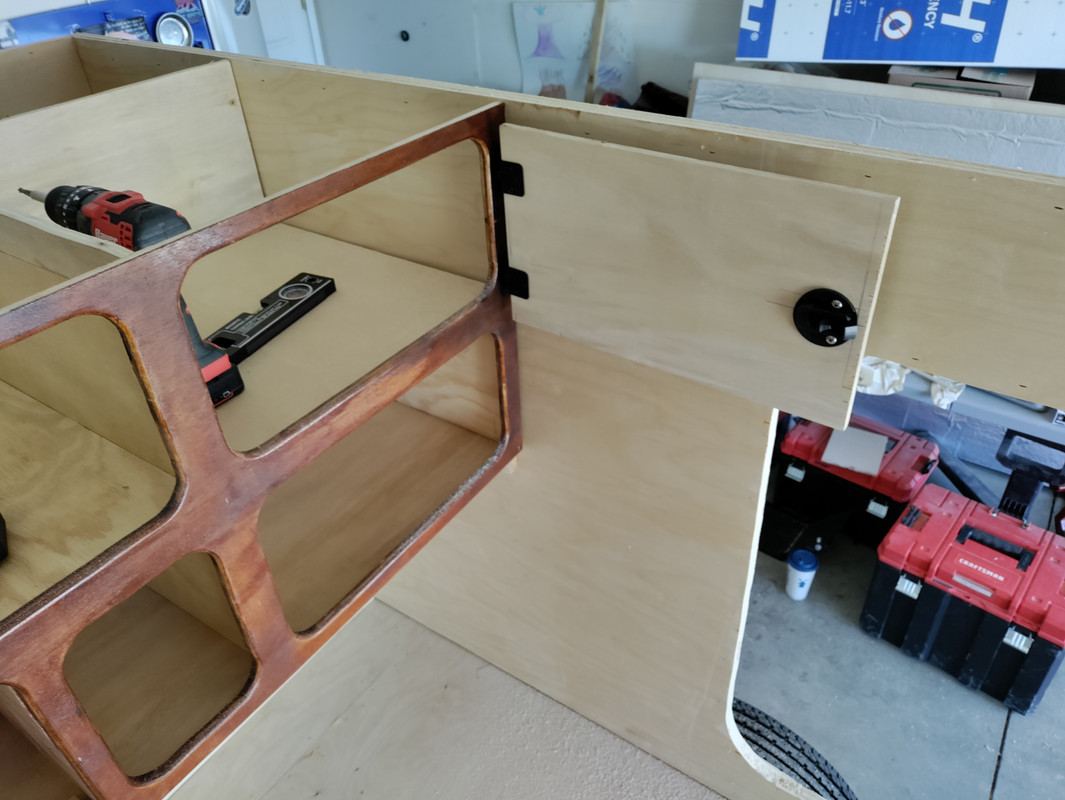

I just bought a doweling jig, and that's what I'm going to use to assemble all the cabinetry. I made some tests on scrap with the pocket hole jig, and with 1/2 ply, I just don't like the way it looks. Lots of dowels and glue will likely be stronger anyways.

Cabinetry will be going in next weekend!

Using Pl premium adhesive, we attached the walls at the base, and screwed them into the 2x4s along the edge of the floor.

I just bought a doweling jig, and that's what I'm going to use to assemble all the cabinetry. I made some tests on scrap with the pocket hole jig, and with 1/2 ply, I just don't like the way it looks. Lots of dowels and glue will likely be stronger anyways.

Cabinetry will be going in next weekend!