Explorer I

- 3,680

- First Name

- Brian

- Last Name

- McGahuey

- Member #

-

23711

- Ham/GMRS Callsign

- GMRS WRMV941

The time has come to build a new off road trailer. While Groot 1.0 has served us well, including a trek down the Idaho BDR, we've decided that it's time to move to a square drop style camper.

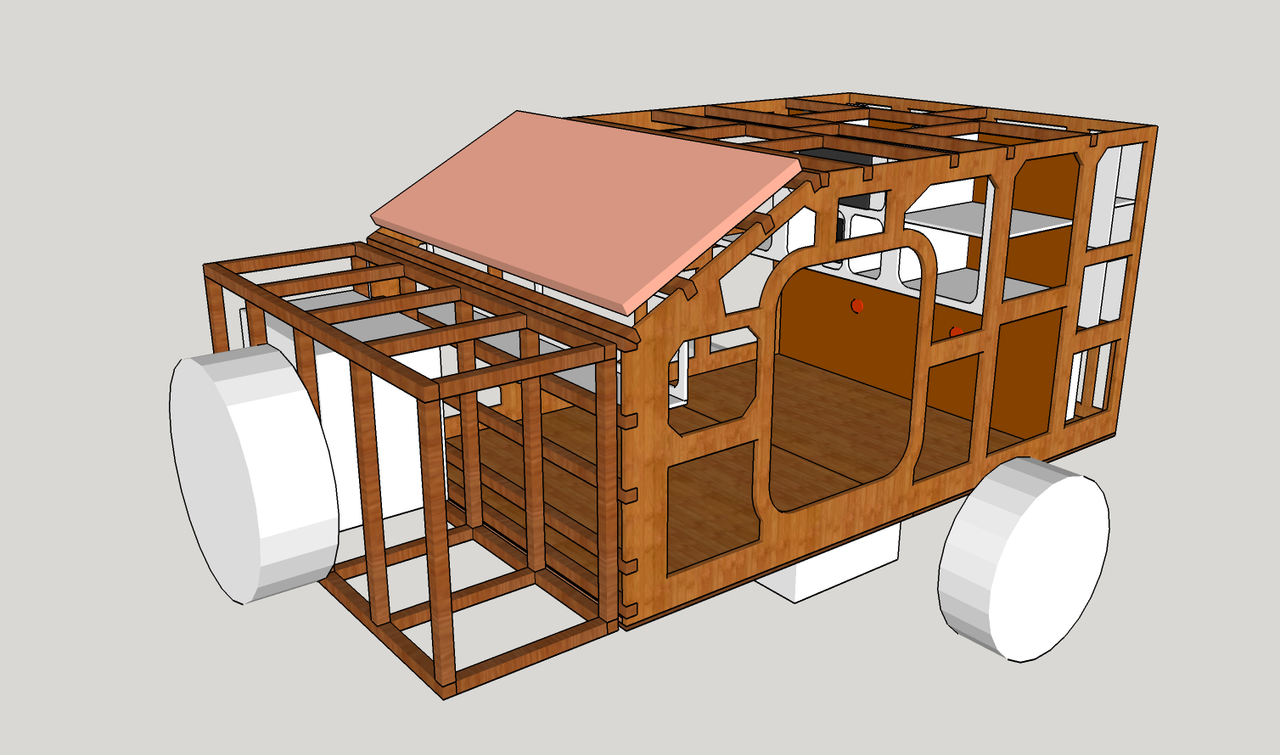

I've begun planning the cabin, while also learning how to use sketchup.

The basic cabin structure will consist of a 1/2 in plywood base, with 1x2 and 3/4 in foam providing insulation and structure, followed by a piece of 1/4 in plywood. a 6 inch mattress will sit on top of this, so more insulation is not really required.

Walls will consist of 1/4 inch outer wall, with 3/4 inch foam and 1x2 providing additional structure, with 1/4 inch interior wall.

the roof will be 1.5 inches thick, with 2x2 spars and 1.5 inch thick foam sandwiched between two layers of 1/4 inch plywood.

Now, I know what you're thinking.....1/4 inch plywood won't be very strong. And normally, you'd be right. The ENTIRE box, including the floor will be coated and strengthed using 4 oz fiberglass. This will not only stiffen the entire box, but will completely waterproof everything.

The exterior dimensions of the cabin will be 96 inches long x 60 inches wide, and will sit on a 5x9 frame consisting of welded 2x2.5 in square tubes.

There's a local trailer manufacturer here in Caldwell that makes utility trailers.

This is the frame I'll be starting with to build on.

All the rails, tailgate and front part bolt off, and the trailer quickly converts to a flatbed.

I'm shooting for a dry weight, with the box of 1500 lbs. The trailer has a gross weight of 2500lbs, and weighs 550 lbs in the above configuration. Taking all the extras off should shave 100 lbs or so off the weight, and I'm anticipating the box to weigh roughly 700lbs or so.

I'll update this as the design evolves.

Let the fun begin!

I've begun planning the cabin, while also learning how to use sketchup.

The basic cabin structure will consist of a 1/2 in plywood base, with 1x2 and 3/4 in foam providing insulation and structure, followed by a piece of 1/4 in plywood. a 6 inch mattress will sit on top of this, so more insulation is not really required.

Walls will consist of 1/4 inch outer wall, with 3/4 inch foam and 1x2 providing additional structure, with 1/4 inch interior wall.

the roof will be 1.5 inches thick, with 2x2 spars and 1.5 inch thick foam sandwiched between two layers of 1/4 inch plywood.

Now, I know what you're thinking.....1/4 inch plywood won't be very strong. And normally, you'd be right. The ENTIRE box, including the floor will be coated and strengthed using 4 oz fiberglass. This will not only stiffen the entire box, but will completely waterproof everything.

The exterior dimensions of the cabin will be 96 inches long x 60 inches wide, and will sit on a 5x9 frame consisting of welded 2x2.5 in square tubes.

There's a local trailer manufacturer here in Caldwell that makes utility trailers.

This is the frame I'll be starting with to build on.

All the rails, tailgate and front part bolt off, and the trailer quickly converts to a flatbed.

I'm shooting for a dry weight, with the box of 1500 lbs. The trailer has a gross weight of 2500lbs, and weighs 550 lbs in the above configuration. Taking all the extras off should shave 100 lbs or so off the weight, and I'm anticipating the box to weigh roughly 700lbs or so.

I'll update this as the design evolves.

Let the fun begin!