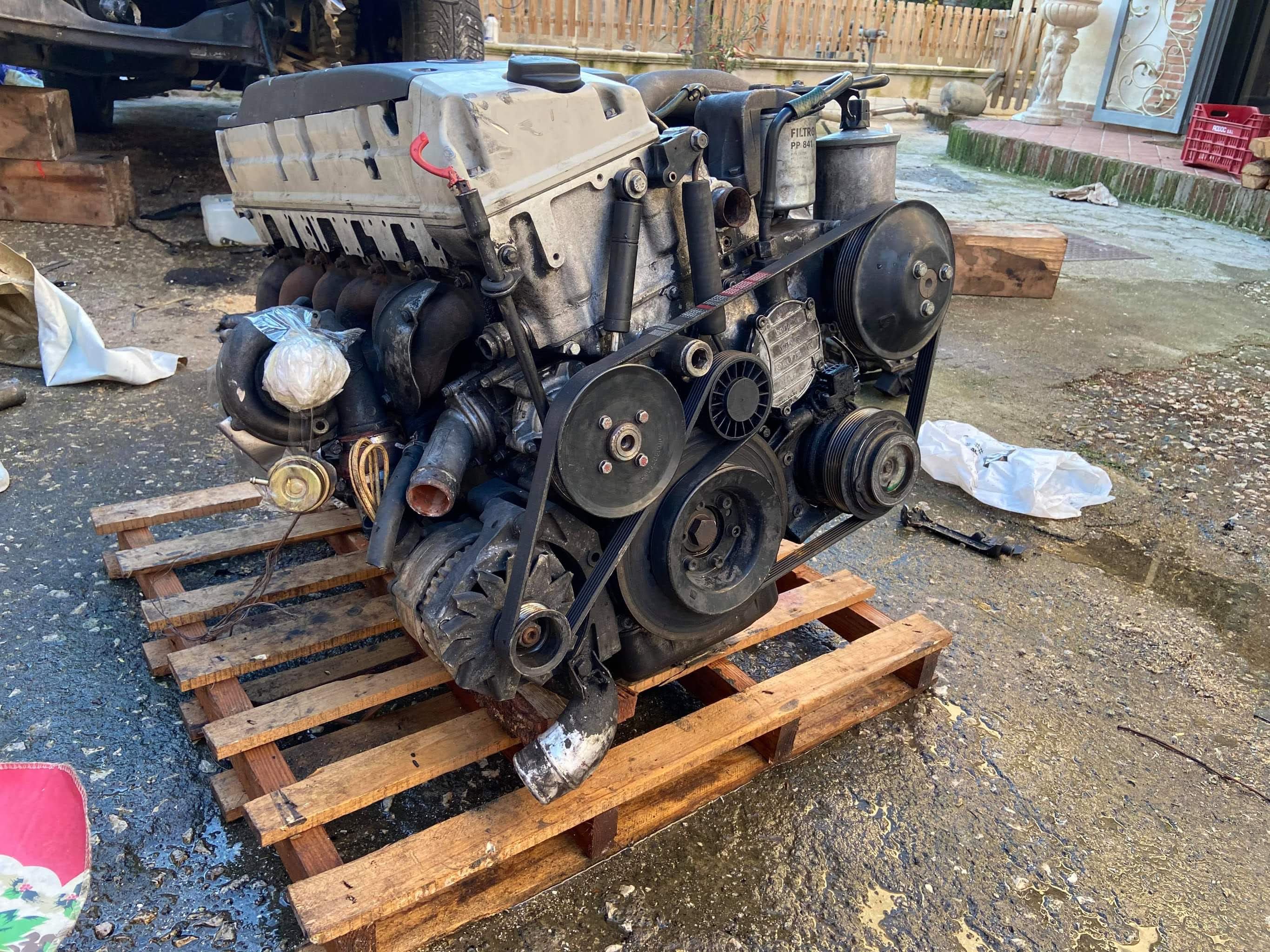

There has been quite a bit going on, but let's start from the beginning.

I knew that the engine head needed a bit of work, however, I did not want to rebuild it myself. I believe that it is a more complex engine component and that it is better to entrust the work on it to an experienced pair of hands. With that in mind and on the recommendation of a friend, I took the head to Martinišće (near Zagreb) and left it in the hands of mechanics at the

Očić workshop. Already during the first quick inspection, they pointed out a few indicators that suggested that the head was in worse condition than expected. The head gasket had obviously failed. The leakage between the cylinders was immediately noticeable, and upon closer examination of the head gasket at home, the leakage was also visible on it. I tell myself that I could have noticed this earlier if I had paid more attention to examining the gasket. This explains the presence of oxidized coolant and some rust on the valves of the fourth cylinder as well. The coolant found its way from one of the channels into the cylinder. Based on the amount of rust in the coolant channels, it seems like the previous owner didn't care much about using the correct coolant and instead used regular tap water. This lack of attention likely played a role in the current condition of the engine.

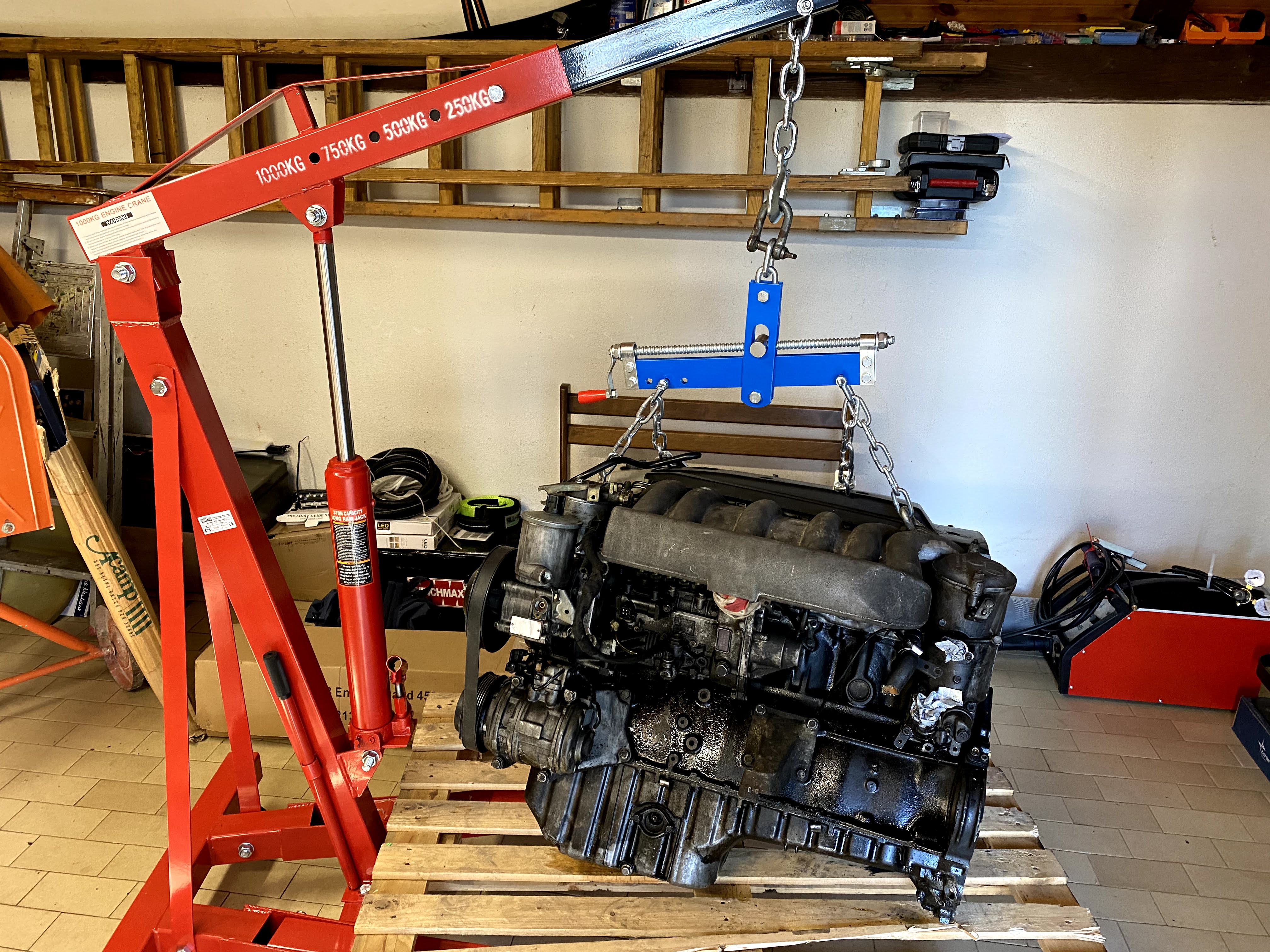

The mechanics took care of the head, and I focused on the rest of the engine. The first challenge of disassembling the bottom part of the engine was removing the balancer. Since the engine didn't have a flywheel (I bought the engine without a flywheel, and I'll have to buy one in the future), I had to "lock" the crankshaft in a more unconventional way. After watching

this video, I came up with the idea to make a similar tool myself. I designed and 3D printed a tool similar to a huge nut using ASA+ plastic filament. With the mentioned tool and large pipe pliers, in theory, I could hold the crankshaft in place. I tested the tool, but only after buying bigger pipe pliers because the printed nut was so damn big. The tool worked, although the plastic got damaged while holding it with the pliers.

Taking apart the rest of the engine went smoothly and soon only the bare engine block was left on the stand.

So, then came the surprise.

To be completely honest, at first, I thought everything was within normal limits. The bearings, with the exception of the fourth one, were in very good condition. However, the condition of the cylinder walls and the fourth piston puzzled me. The cylinder walls had no major scratches and showed low signs of wear in some areas. In those areas, you could see the "crosshatch" marks from honing. On the other hand, the higher areas of the cylinder walls looked quite worn and had areas that resembled water-scale flakes. I found it interesting that these areas didn't create grooves where you could get your fingernail stuck.

At this point, I wanted to keep the original pistons, so I measured the cylinders. All cylinders, including the fourth one, which was also a bit rusty, were within the prescribed 0.2mm tolerance.

Also, I bought a 30L ultrasonic cleaner for cleaning smaller engine parts. To be honest, I didn't even know these existed until now.

At this point, Očić informed me that the engine head was cracked. They said it could be repaired by welding. I reluctantly agreed to this. I was initially angry and then quite disappointed with the situation. But once I came to terms with it, I received another call. The head had failed the pressure test and showed signs of cracks on all cylinders. I was almost ready to give up. I felt angry at the previous owner who had shown no care for the engine's maintenance, and angry at myself for investing a lot of money into this project.

After sleeping on it for a couple of nights, I decided to push through and finish the project. I started looking for another engine head. I considered buying another engine, but the prices had gone up and these engines were becoming rarer. During my search, I came across several OM606 engine heads without a turbo, but they were apparently not exactly the same. After a few weeks of searching, I finally found and purchased an engine head from an OM606.962 engine, which is a turbo variant of the OM606 engine.

By purchasing the second engine head, it seemed like the project was headed in the right direction. This feeling was reinforced by a mechanic who is currently rebuilding an OM606 engine himself. He saw some of my questions on Facebook in the

OM606 Superturbo group and contacted me. After our conversation, I took the engine block to him for blasting, honing, and other machining.

After our discussion, I was convinced that the only right path was a complete engine block rebuild, honing the cylinders to a 0.5mm larger diameter, and purchasing new pistons. At the same time, I decided to replace the connecting rods with much stronger, forged

ACM or

Hench Performance connecting rods.

Finding larger pistons turned out to be a more challenging task than expected. I was looking for 87.5mm pistons from the German manufacturer NPR. I found several European sellers, but none had them in stock or could supply them. In the end, I found them at

BenzForce in the USA and ordered the last six in stock.

Discover the magic of the internet at Imgur, a community powered entertainment destination. Lift your spirits with funny jokes, trending memes, entertaining gifs, inspiring stories, viral videos, and so much more from users.

imgur.com

Then, the replacement engine head arrived.

Discover the magic of the internet at Imgur, a community powered entertainment destination. Lift your spirits with funny jokes, trending memes, entertaining gifs, inspiring stories, viral videos, and so much more from users.

imgur.com

During the removal of the glow plugs from the new head, which are notorious for breaking and seizing in this engine, I managed to break three glow plugs. At that moment, I started to sweat again. However, everything should turn out fine in the end. I took the new head to the mechanics at the Očić workshop, where they will remove the glow plugs and overhaul the head.

Hopefully, this time, I will have better luck with the head.