Member III

- 2,827

- First Name

- Joshua

- Last Name

- Downs

- Member #

-

20468

- Ham/GMRS Callsign

- KK6RBI / WQYH678

- Service Branch

- USMC 03-16, FIRE/EMS

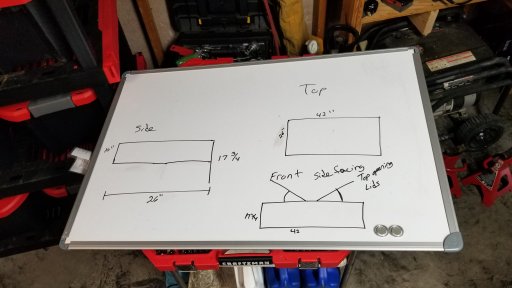

I'll be building a modular storage system for the XJ.

Here is part of the first part. I didn't want it to go the top of the seat, just to the top of the wheel wells so when the other parts are added to it sleeping will not be a big deal. This should give me plenty of in box storage for daily use while still maintaining some extra cargo space on top. The top will have two hinged lids one facing forward the other to the rear so I can access the box with the hatch closed when other parts of the system are in place. The rear of the box will also have a "tailgate" for loading and unloading things from inside the box when things are loaded on top of the box. I didn't want to go with a drawer system due to increased complexity, cost and decreased storage space.

Material's used at this point and probably thoughout the whole project will be 16ga 1x1 steel tubing as the skeleton of the system with 1/4 inch plywood on no load supporting sides and 1/2 inch on the lids and "tailgate" which may be expected to support the loads. 1x1 angle iron (1/8 inch) will be used as stops for the doors and latches are going to be similar to a standard tool box but spring loaded to help remove rattle.

Here is part of the first part. I didn't want it to go the top of the seat, just to the top of the wheel wells so when the other parts are added to it sleeping will not be a big deal. This should give me plenty of in box storage for daily use while still maintaining some extra cargo space on top. The top will have two hinged lids one facing forward the other to the rear so I can access the box with the hatch closed when other parts of the system are in place. The rear of the box will also have a "tailgate" for loading and unloading things from inside the box when things are loaded on top of the box. I didn't want to go with a drawer system due to increased complexity, cost and decreased storage space.

Material's used at this point and probably thoughout the whole project will be 16ga 1x1 steel tubing as the skeleton of the system with 1/4 inch plywood on no load supporting sides and 1/2 inch on the lids and "tailgate" which may be expected to support the loads. 1x1 angle iron (1/8 inch) will be used as stops for the doors and latches are going to be similar to a standard tool box but spring loaded to help remove rattle.