I picked up a 1951 M100 trailer a few years ago with no intentions of building it out any further than some bigger tires for dispersed tent camping trips in Colorado. However, after thinking about logistics of finding BLM/NFS campsites that could fit a Jeep, utility trailer, tent(s), and the rest of family camp setup, I decided to put the tent on the trailer and build it. The trailer was solid but already modified by the PO with a flimsy rack, welded ball coupler, and a hacked and then unhacked tailgate. Parts have been accumulated slowly and mostly second hand to keep budget down. This is my first welding project with YouTube as training, so hoping for the best, but so far so good.

Plans:

extend tub walls up 18" with exo-frame

roll up tonneau cover

extended tongue

tongue box

off-road coupler

tongue jack w/ wheel

tube fenders

rear bumper with hitch receiver

swing out tailgate

new 3500lb axle, electric brakes, parking brake

probably new leaf springs to account for added weight

35" tires on Jeep JK wheels

RTT and 270 awning on lift platform, linear actuators

battery system for lights, break away switch, actuators, and camping accessories.

As received:

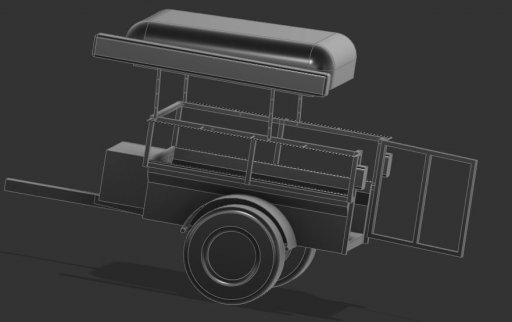

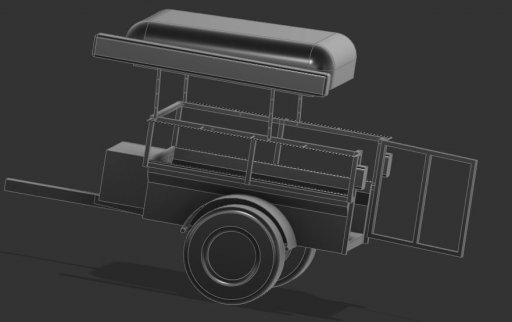

Concept:

After scraping the caulk from the back wall of the tub, the tailgate looks to have been cut out with a hatchet.

Plans:

extend tub walls up 18" with exo-frame

roll up tonneau cover

extended tongue

tongue box

off-road coupler

tongue jack w/ wheel

tube fenders

rear bumper with hitch receiver

swing out tailgate

new 3500lb axle, electric brakes, parking brake

probably new leaf springs to account for added weight

35" tires on Jeep JK wheels

RTT and 270 awning on lift platform, linear actuators

battery system for lights, break away switch, actuators, and camping accessories.

As received:

Concept:

After scraping the caulk from the back wall of the tub, the tailgate looks to have been cut out with a hatchet.

Last edited: