Off-Road Ranger I

I have one Overland Bound member badge on the back of my FJ, and I've been planning to mount the other one somewhere up front for a while. I hadn't found an easy way to get a clean mount - you need something with a nice flat surface for the badge to stick to, and then you need a way to securely mount it on the grille. None of the grille badge holders I found fit the OB badge well.

If I had a workshop I could probably cut one from wood or plastic, but I live in the city, so I needed an easy way to fab one. So I used 3D printing, which let me generate a mount that's exactly the right size to match the OB badge (6cm diam), and has the right holes and grooves so I could zip-tie it securely onto the grille.

I'm posting the info here because I haven't seen any other threads about 3D printing, and it seems like it might be useful for both anyone who wants to repro this project, and any other small fiddly plastic part you might want for your dashboard, etc.

(Don't try to print a lift kit or bumper.)

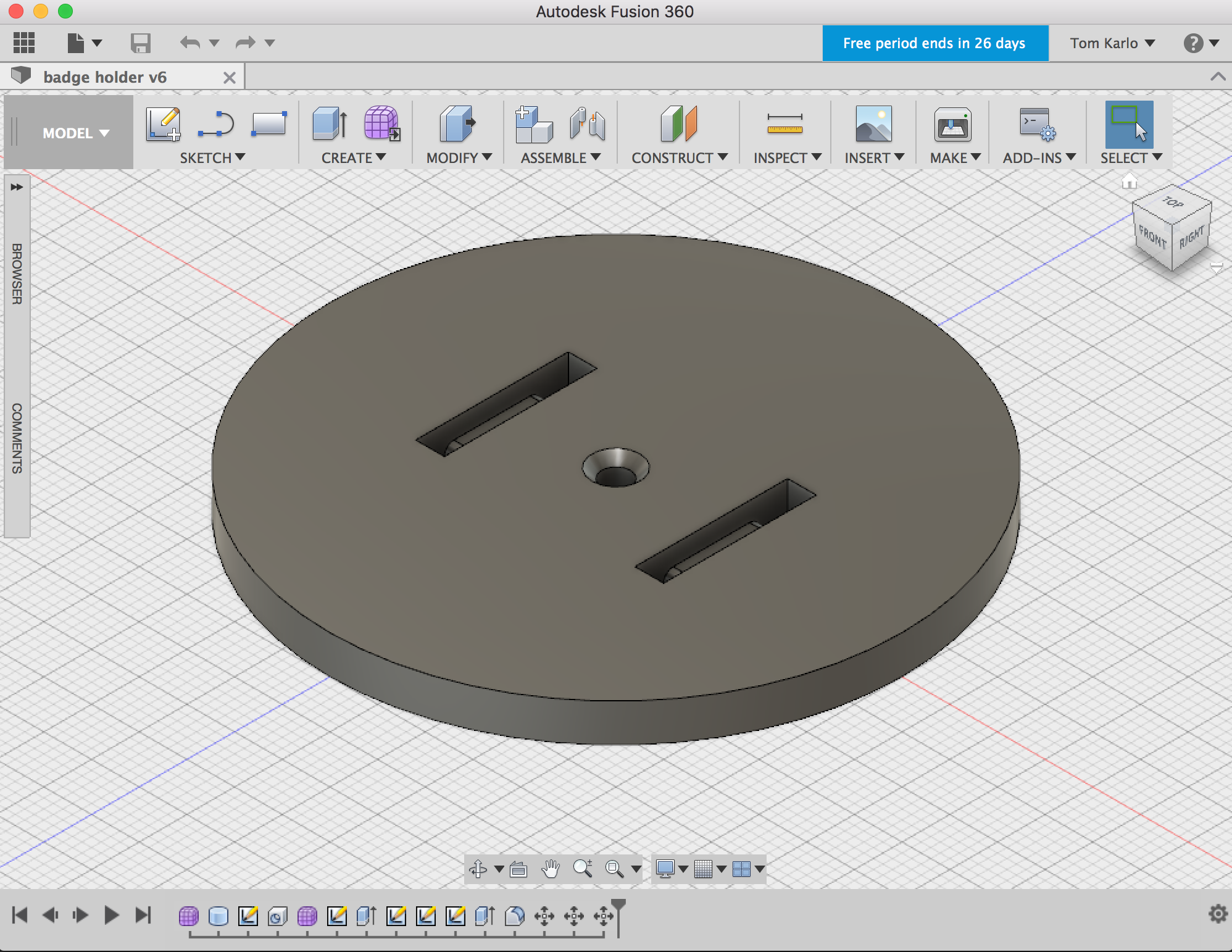

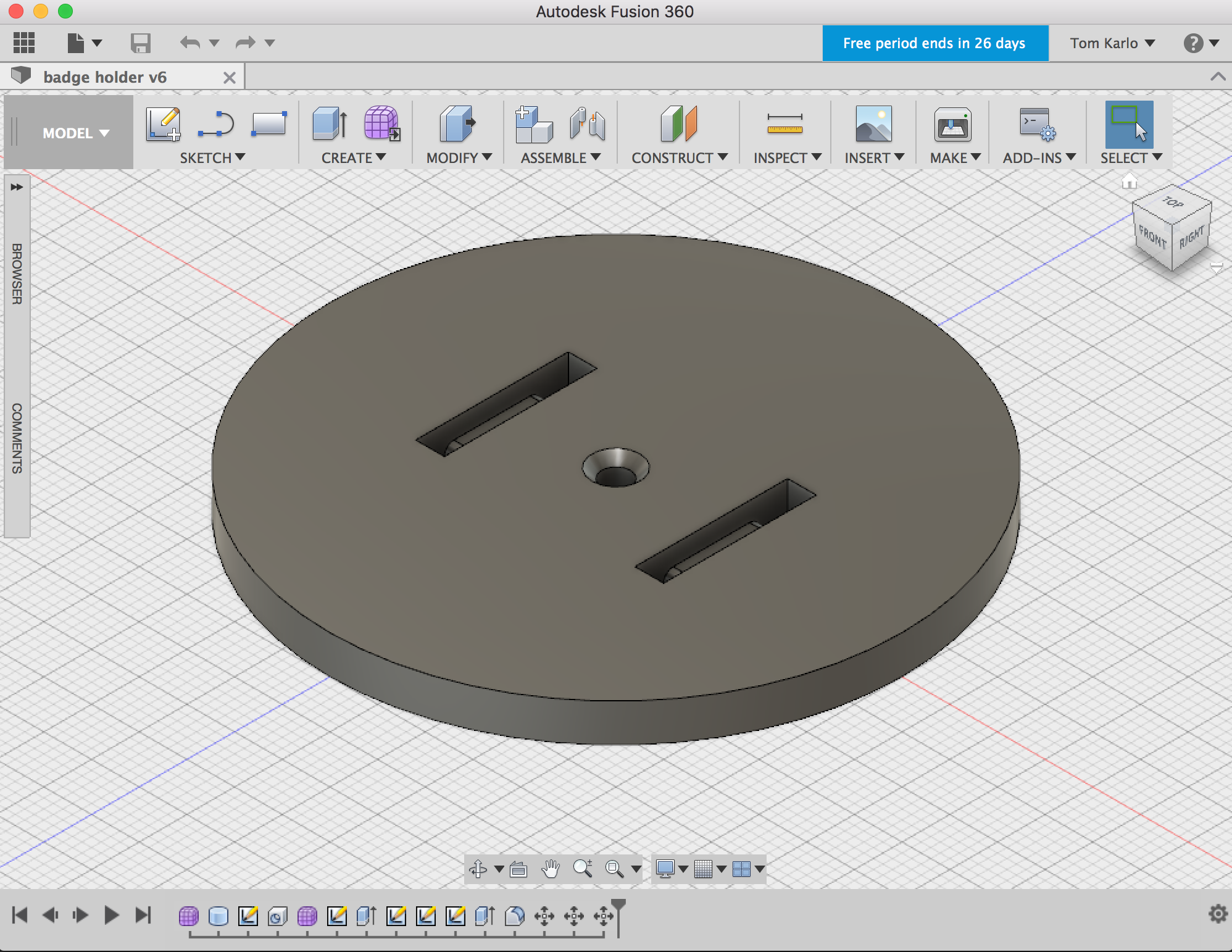

I generated the 3D shape file (STL) using Fusion360, which is free to trial. (Blender is a great free and open source option as well.)

It's basically a 5mm thick wafer, 6cm in diameter. If I was going to improve it, I'd add a 1x1 mm "rim" around the edge of the side the badge goes on, to fill the gap between the adhesive and the edge of the badge. I was a bit worried this might interfere with getting the badge to stick on well, however. The groves are there so you can wrap two zip-ties through the holes and have them below the surface of the mount, so they don't interfere with the badge sticking on.

I saved the model as an STL file and sent it via email to my local UPS store. Shapeways is cheaper, but I wanted this done fast - I emailed the file on Friday and picked up the finished "part" on Saturday. It was about $25 from UPS, I'd guess it would be about $10 plus shipping from Shapeways. FWIW, they said it took an hour to print, which sounded terrible to me until I remembered it's just an hour of a robot plotting this out, rather than an hour spent by a person fabbing it (and you can reproduce it perfectly.)

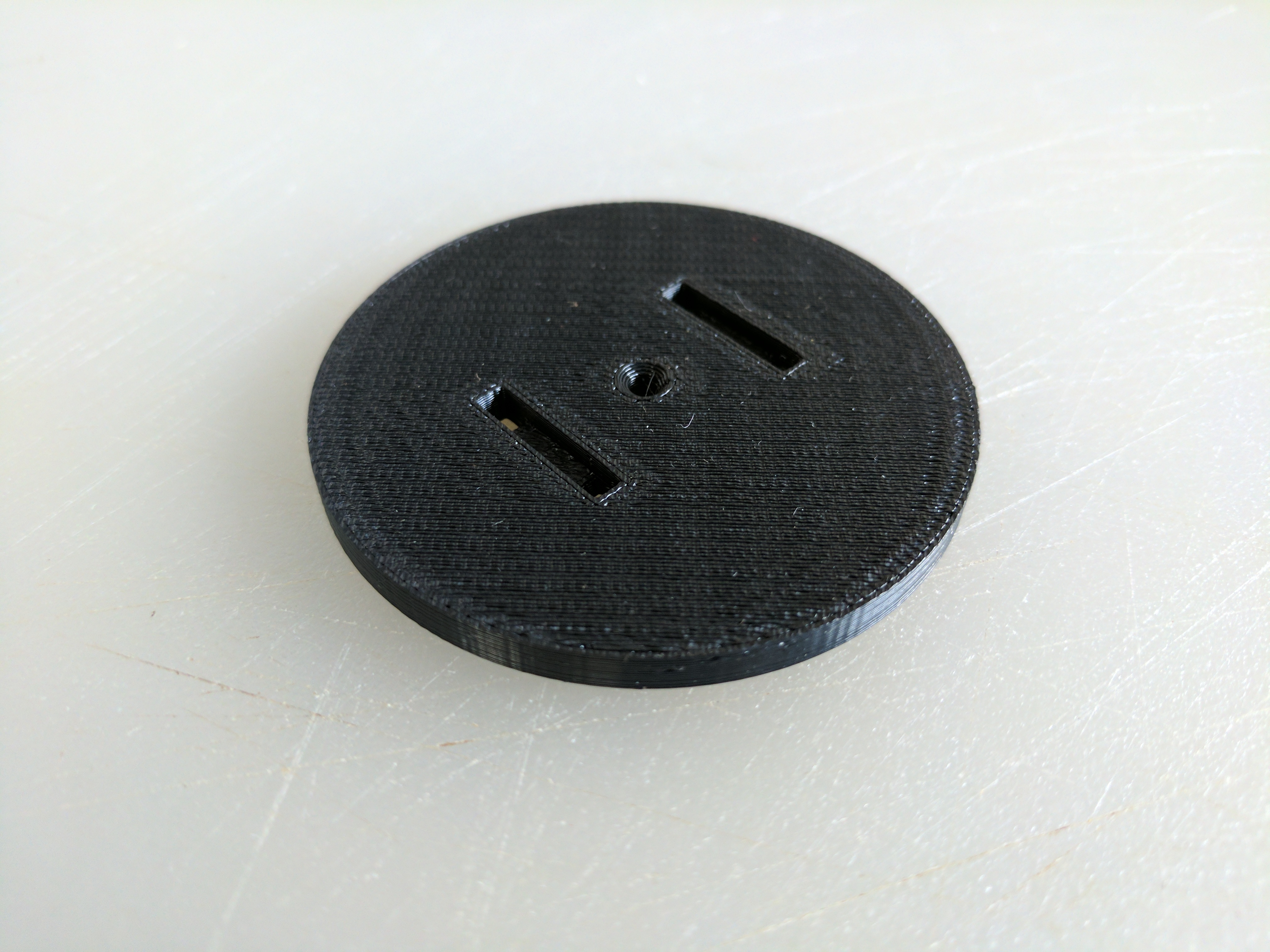

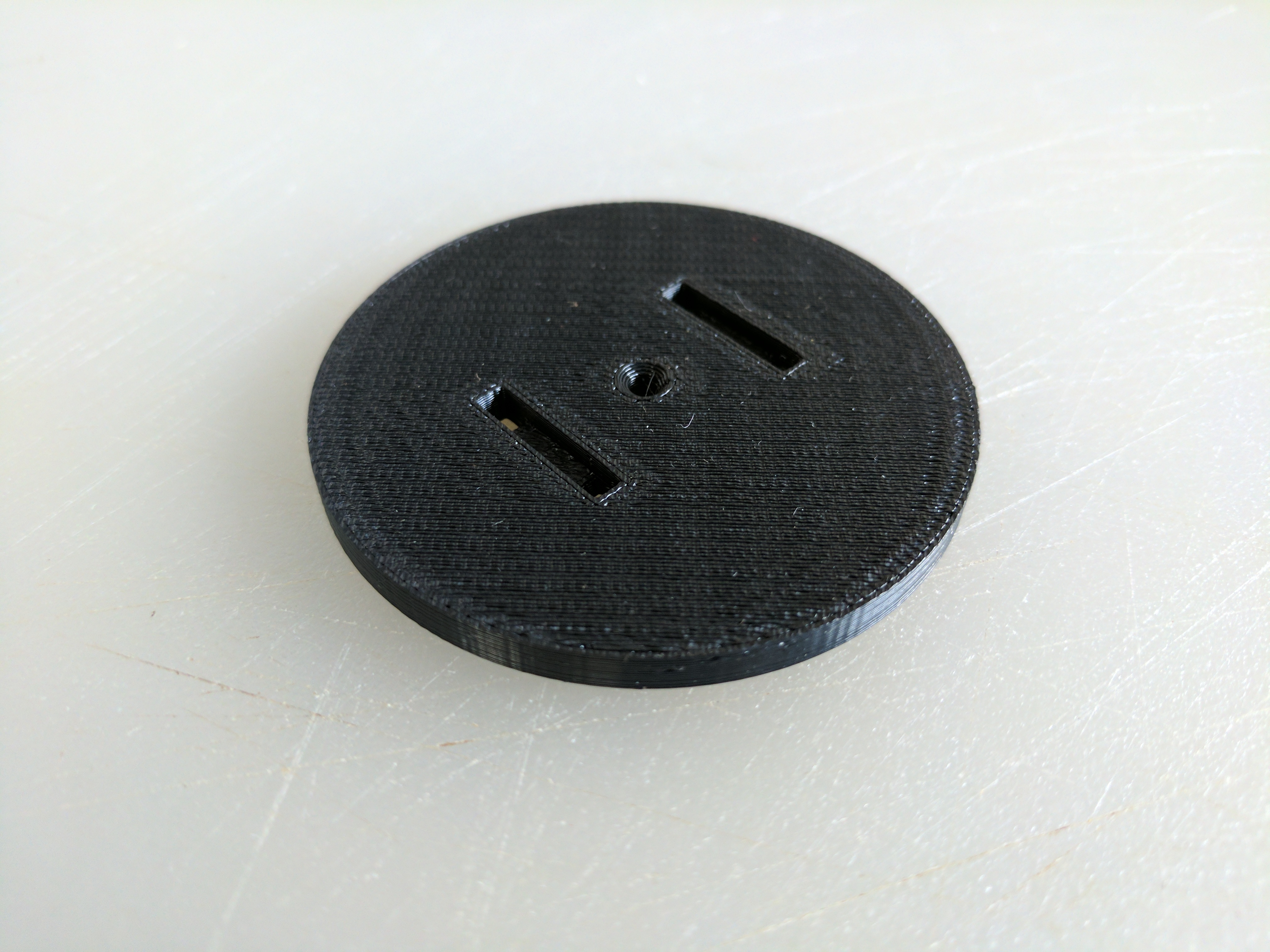

Here's the raw part, straight off the printer:

I sanded down both sides on a flat surface to reduce the texture - again to improve adhesion - then cleaned both sides off. I don't think there's any oils on 3D prints but you might want to rub both faces with alcohol to ensure best stick.

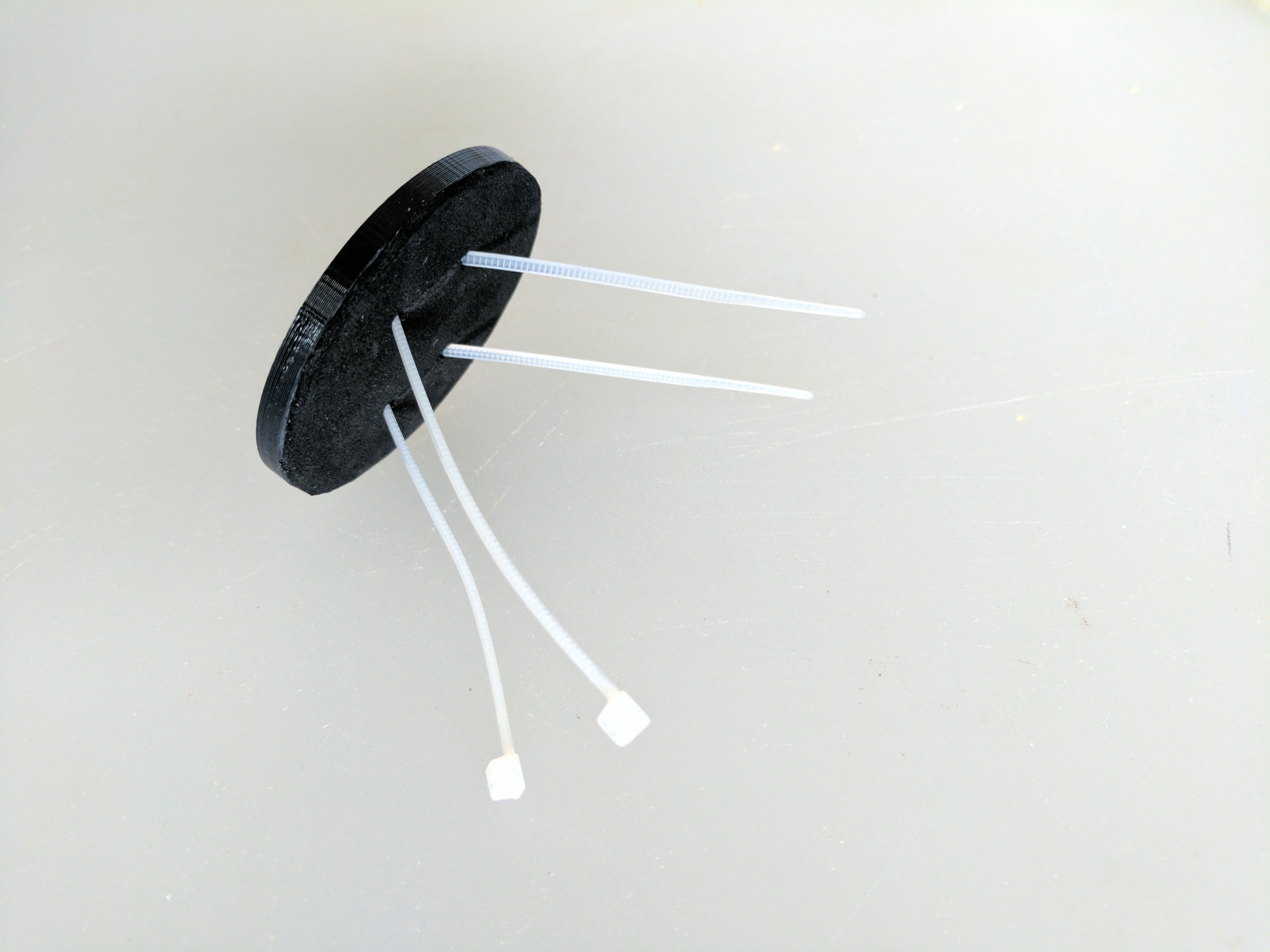

I then cut out a circle of 2mm thick, self-aheasive foam for the back - this helps keep the badge in place from rotating or jiggling, and just makes for a better mount in general. The foam gets stuck on the back of the plate (the side with no grooves). You could probably skip the foam if you don't have any, or just use some foam tape instead.

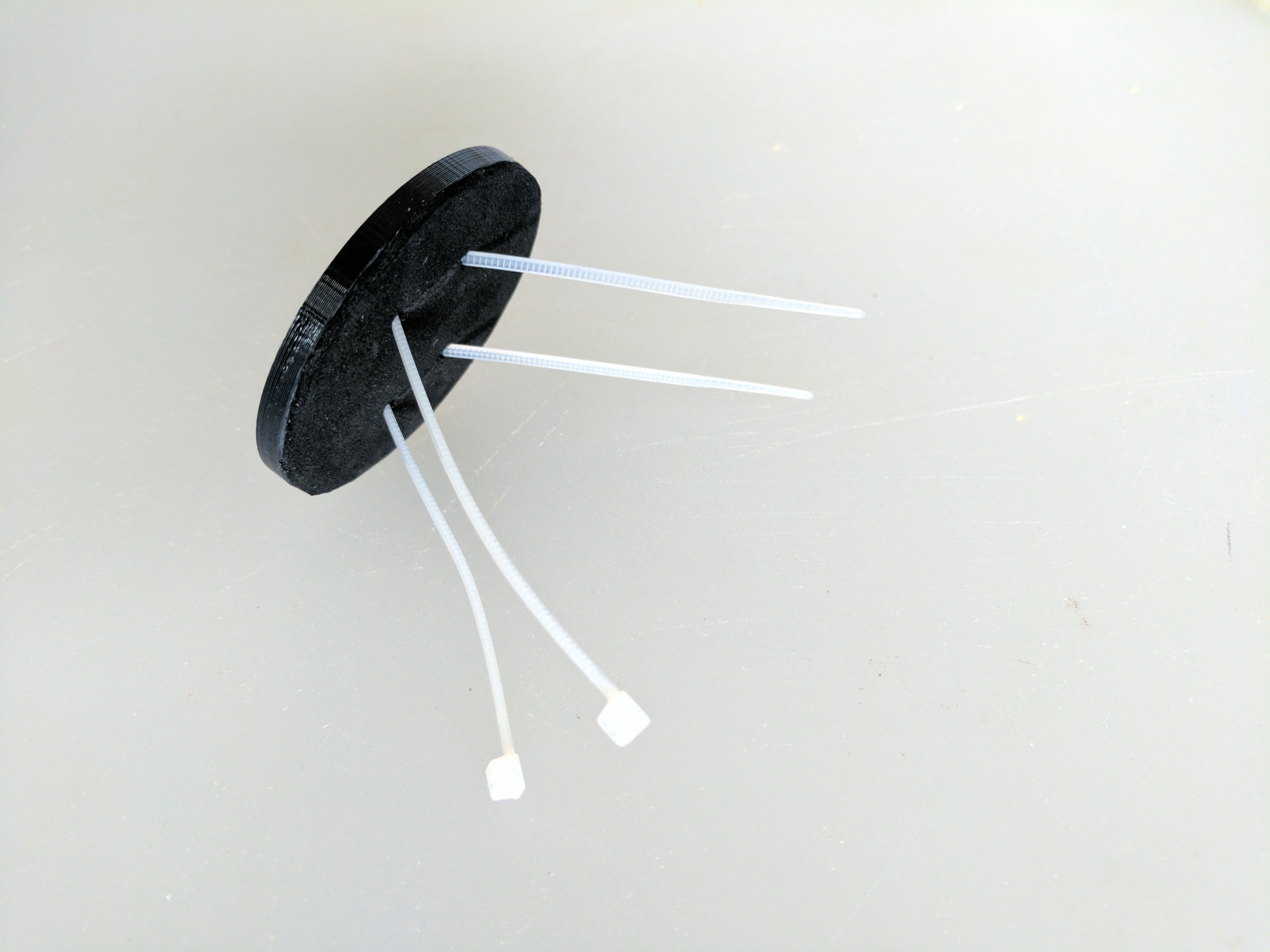

Here's the finished mount with the foam and zip ties installed:

This is how it's mounted on my grille, seen from the inside:

(In retrospect I maybe wish I used heavier zip ties, but they seem fine, and it's not that much weight.)

And seen from the front of the FJ:

Once this was done I wiped the mount plate and carefully stuck on the OB badge. I waited to do this until after the plate was firmly mounted in case I had to replace a zip tie or if the mount didn't go on straight.

Finally, while researching this post I found out how to post the 3D file to Shapeways so you can just order the part directly without using the 3D software (if you just want it as-is.) Here's the link to Shapeways - it's ~$9 for the plastic one, or if you're rich, you can spend about $60 for a steel one. (Note: I don't make any money off this if you buy it from Shapeways -- everything they're charging is their fee for printing the market.)

Get the part at Shapeways.

You can also download the STL file if you want to modify / improve it.

If I had a workshop I could probably cut one from wood or plastic, but I live in the city, so I needed an easy way to fab one. So I used 3D printing, which let me generate a mount that's exactly the right size to match the OB badge (6cm diam), and has the right holes and grooves so I could zip-tie it securely onto the grille.

I'm posting the info here because I haven't seen any other threads about 3D printing, and it seems like it might be useful for both anyone who wants to repro this project, and any other small fiddly plastic part you might want for your dashboard, etc.

(Don't try to print a lift kit or bumper.)

I generated the 3D shape file (STL) using Fusion360, which is free to trial. (Blender is a great free and open source option as well.)

It's basically a 5mm thick wafer, 6cm in diameter. If I was going to improve it, I'd add a 1x1 mm "rim" around the edge of the side the badge goes on, to fill the gap between the adhesive and the edge of the badge. I was a bit worried this might interfere with getting the badge to stick on well, however. The groves are there so you can wrap two zip-ties through the holes and have them below the surface of the mount, so they don't interfere with the badge sticking on.

I saved the model as an STL file and sent it via email to my local UPS store. Shapeways is cheaper, but I wanted this done fast - I emailed the file on Friday and picked up the finished "part" on Saturday. It was about $25 from UPS, I'd guess it would be about $10 plus shipping from Shapeways. FWIW, they said it took an hour to print, which sounded terrible to me until I remembered it's just an hour of a robot plotting this out, rather than an hour spent by a person fabbing it (and you can reproduce it perfectly.)

Here's the raw part, straight off the printer:

I sanded down both sides on a flat surface to reduce the texture - again to improve adhesion - then cleaned both sides off. I don't think there's any oils on 3D prints but you might want to rub both faces with alcohol to ensure best stick.

I then cut out a circle of 2mm thick, self-aheasive foam for the back - this helps keep the badge in place from rotating or jiggling, and just makes for a better mount in general. The foam gets stuck on the back of the plate (the side with no grooves). You could probably skip the foam if you don't have any, or just use some foam tape instead.

Here's the finished mount with the foam and zip ties installed:

This is how it's mounted on my grille, seen from the inside:

(In retrospect I maybe wish I used heavier zip ties, but they seem fine, and it's not that much weight.)

And seen from the front of the FJ:

Once this was done I wiped the mount plate and carefully stuck on the OB badge. I waited to do this until after the plate was firmly mounted in case I had to replace a zip tie or if the mount didn't go on straight.

Finally, while researching this post I found out how to post the 3D file to Shapeways so you can just order the part directly without using the 3D software (if you just want it as-is.) Here's the link to Shapeways - it's ~$9 for the plastic one, or if you're rich, you can spend about $60 for a steel one. (Note: I don't make any money off this if you buy it from Shapeways -- everything they're charging is their fee for printing the market.)

Get the part at Shapeways.

You can also download the STL file if you want to modify / improve it.