Advocate I

I haven't followed up in a while, but that first test run did find one issue besides just the fenders (which have been taken care of, as you can see earlier in the thread). The rear axle has so much travel and articulation, we found the end of the articulation of the heims on the end-links.

Both heims were on the same plane, or in the same orientation if you will. They are this style:

The way they were setup, the stud went side to side, as opposed to front to back, and both pointed outward (so the driver's side has the heim itself was inboard of the sway bar arm, and pointed out to the left, the passenger side was opposite being inboard and point out to the right). I had a little trouble finding great data on these heims, but mostly what I found is they're good for ~20-24 degrees of free movement. If you take a look at this pic:

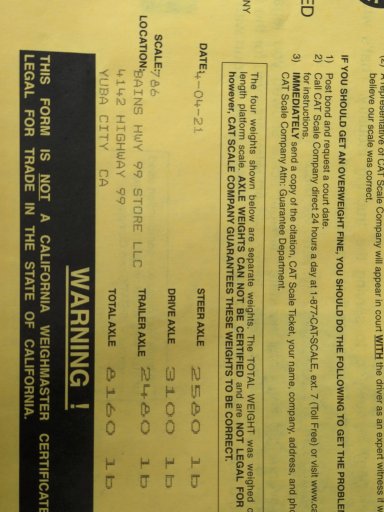

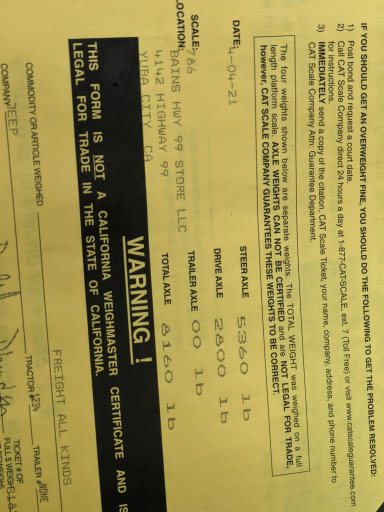

Doing some eye-balling of the angle of the axle-housing as compared to the "chassis" (yes, it's unibody) it looks like it's in the ballpark (use the bumper as a good reference for the chassis angle). Trying to get a bit more scientific the axle vs. bumper is prob a bit over 20 degrees:

That probably shouldn't be a problem, or I wouldn't have thought it would, but it definitely bound up:

I have to say, I'm impressed the end links hung in there enough to actually bend the fabricated steel arms. But they did. The driver's side was only a little tweaked, but the passenger side as you can see got pretty messed up.

So what's the fix?

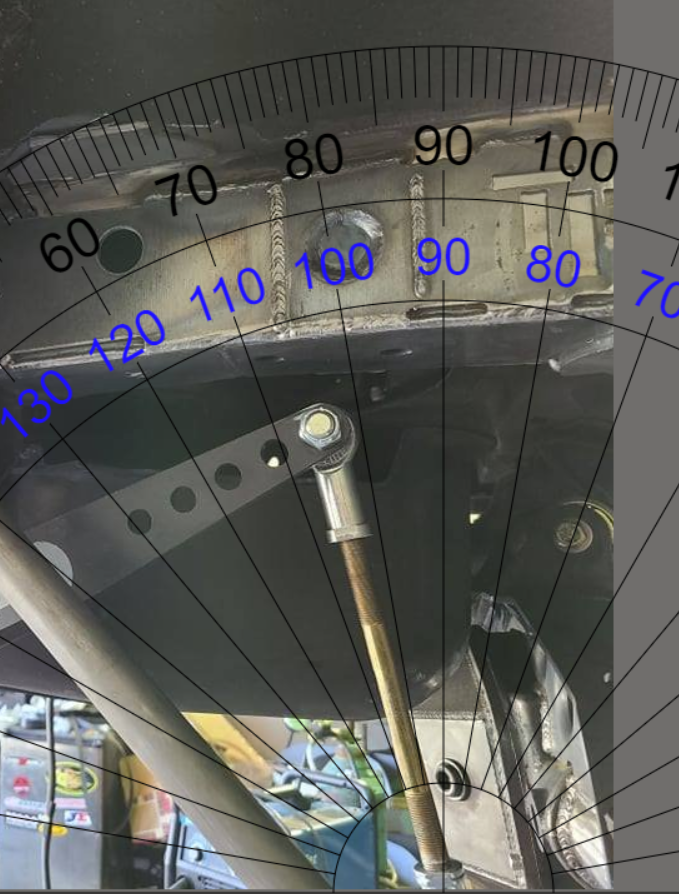

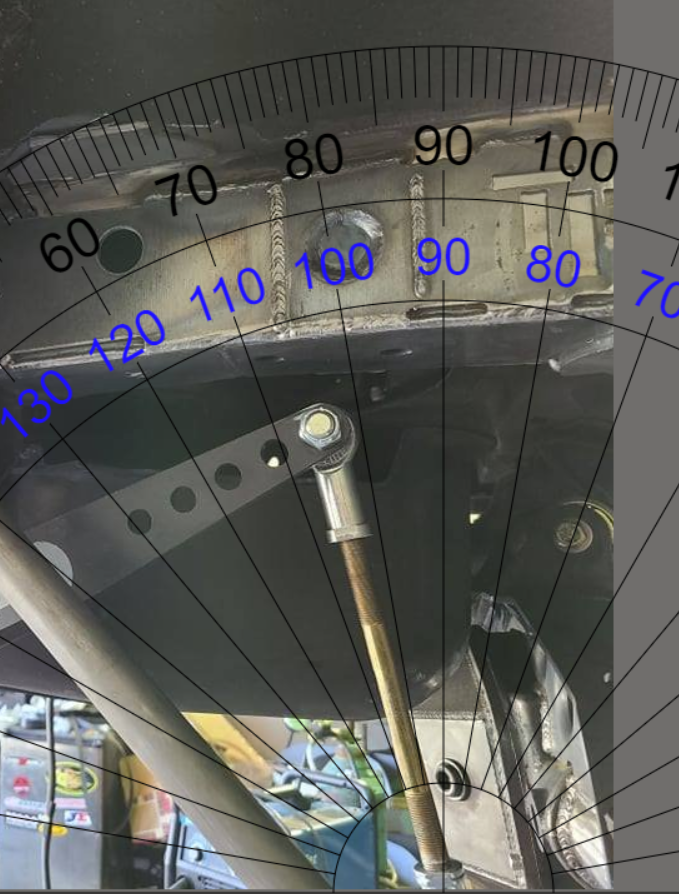

Well, for one we're going to turn the lower heim 90 degrees so the studs point directly forward. This will mean the axle-tab will be a flat-bottom |__| "u" shape instead of just a singular tab, which will make it much stronger. But also, the heim will be oriented so that it is rotating about the mounting point, where it has infinite angularity. Now, that does mean that heim could potentially bind as the end-link angles fore and aft during the arm's swing through its radius. I think we're okay though, because the max angularity as isn't much:

Here you can see it's just under 20 degrees (90-70). But, to make it even better we're moving the bottom mounting point out about an inch or so, which should bring it way closer to vertical. Same story under full-bump:

So, that should really take care of it. Still, we're swapping the fabricated arms out for the forged arms like I have on the front:

Then there's the aforementioned stronger "u" shaped tabs (which will also be boxed on the bottom, with some openings to let mud/water out). On top of that, we're going 1" shorter on the limit straps. While not drastic, it should help a bit and I think my droop previously was sort of unnecessarily ridiculous:

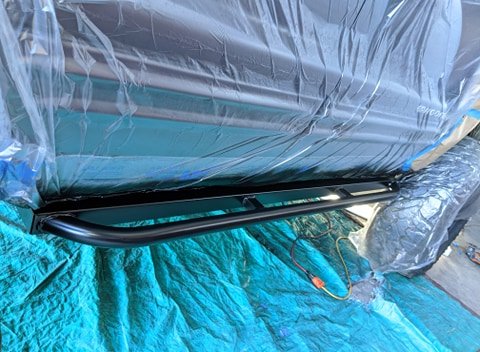

So that's one issue that's getting addressed. Also, doing some clean-up and re-painting things with POR-15. Just the last few months at my buddy's shop which is close to the ocean has started a lot of surface rust. So, I'm addressing it now before it's coated and I can never really get it clean and bare for paint again.

Both heims were on the same plane, or in the same orientation if you will. They are this style:

The way they were setup, the stud went side to side, as opposed to front to back, and both pointed outward (so the driver's side has the heim itself was inboard of the sway bar arm, and pointed out to the left, the passenger side was opposite being inboard and point out to the right). I had a little trouble finding great data on these heims, but mostly what I found is they're good for ~20-24 degrees of free movement. If you take a look at this pic:

Doing some eye-balling of the angle of the axle-housing as compared to the "chassis" (yes, it's unibody) it looks like it's in the ballpark (use the bumper as a good reference for the chassis angle). Trying to get a bit more scientific the axle vs. bumper is prob a bit over 20 degrees:

That probably shouldn't be a problem, or I wouldn't have thought it would, but it definitely bound up:

I have to say, I'm impressed the end links hung in there enough to actually bend the fabricated steel arms. But they did. The driver's side was only a little tweaked, but the passenger side as you can see got pretty messed up.

So what's the fix?

Well, for one we're going to turn the lower heim 90 degrees so the studs point directly forward. This will mean the axle-tab will be a flat-bottom |__| "u" shape instead of just a singular tab, which will make it much stronger. But also, the heim will be oriented so that it is rotating about the mounting point, where it has infinite angularity. Now, that does mean that heim could potentially bind as the end-link angles fore and aft during the arm's swing through its radius. I think we're okay though, because the max angularity as isn't much:

Here you can see it's just under 20 degrees (90-70). But, to make it even better we're moving the bottom mounting point out about an inch or so, which should bring it way closer to vertical. Same story under full-bump:

So, that should really take care of it. Still, we're swapping the fabricated arms out for the forged arms like I have on the front:

Then there's the aforementioned stronger "u" shaped tabs (which will also be boxed on the bottom, with some openings to let mud/water out). On top of that, we're going 1" shorter on the limit straps. While not drastic, it should help a bit and I think my droop previously was sort of unnecessarily ridiculous:

So that's one issue that's getting addressed. Also, doing some clean-up and re-painting things with POR-15. Just the last few months at my buddy's shop which is close to the ocean has started a lot of surface rust. So, I'm addressing it now before it's coated and I can never really get it clean and bare for paint again.