I've had the bronco for about 12 years. Needed some work when I got it.

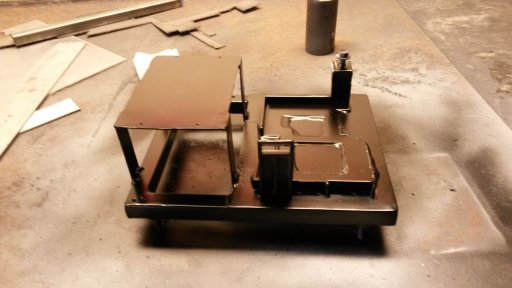

So I fixed some rust and started making changes.

It got a little more involved than I had hoped.

It got a little more involved than I had hoped.

But eventually we started spraying bed liner on it.

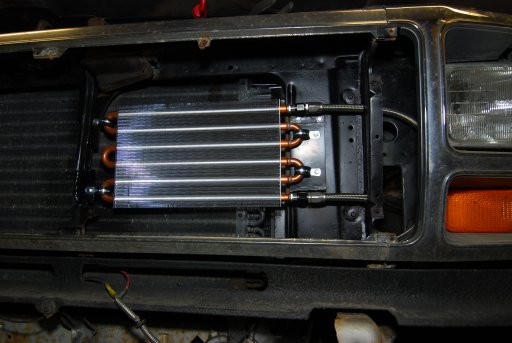

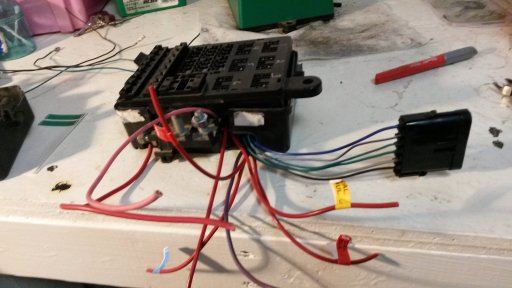

After all the body stuff was done It was time to start on the rest of the stuff. The old engine was tired. The axles where open diffs with 3.55 gears. And the interior needed some help.

After all the body stuff was done It was time to start on the rest of the stuff. The old engine was tired. The axles where open diffs with 3.55 gears. And the interior needed some help.

So I fixed some rust and started making changes.

It got a little more involved than I had hoped.

It got a little more involved than I had hoped.

But eventually we started spraying bed liner on it.

After all the body stuff was done It was time to start on the rest of the stuff. The old engine was tired. The axles where open diffs with 3.55 gears. And the interior needed some help.

After all the body stuff was done It was time to start on the rest of the stuff. The old engine was tired. The axles where open diffs with 3.55 gears. And the interior needed some help.

![081500_1439[00].jpg](/forums/data/attachments/44/44196-f38a02d972f6471df5c548cc98cbfd8d.jpg)

![032800_1142[00].jpg](/forums/data/attachments/44/44207-ad52d4f790e09577dc956e2be3874119.jpg)