Explorer I

- 3,680

- First Name

- Brian

- Last Name

- McGahuey

- Member #

-

23711

- Ham/GMRS Callsign

- GMRS WRMV941

This is the way.

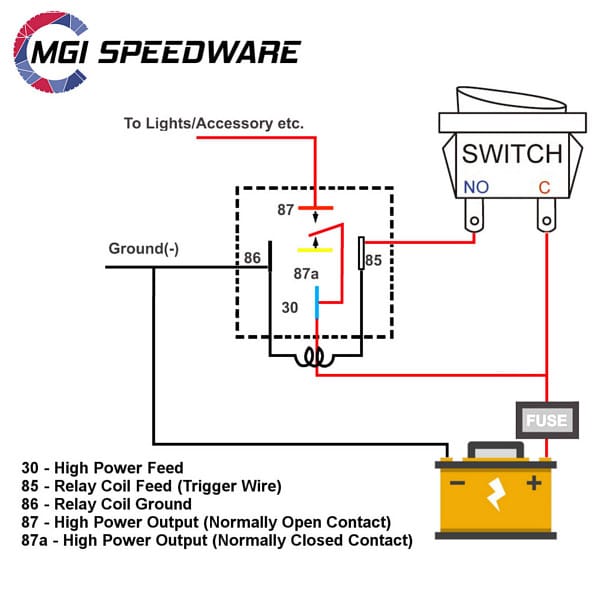

I've not installed my DC-DC charger yet. I'm not going to bother with solar in my rig. I'll save that for the trailer.

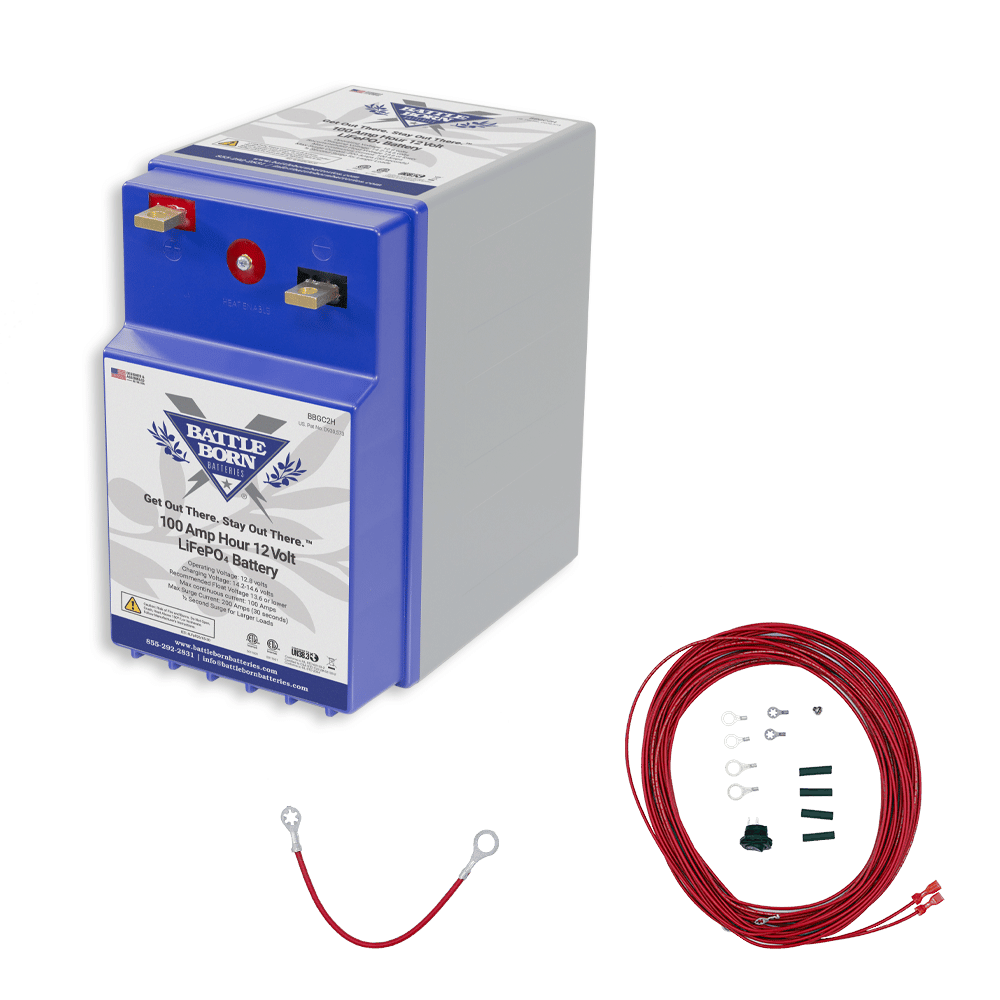

I'd rather use a lifepo4 battery in the rig, but may end up going agm just to save cost. At least to start.

I've not installed my DC-DC charger yet. I'm not going to bother with solar in my rig. I'll save that for the trailer.

I'd rather use a lifepo4 battery in the rig, but may end up going agm just to save cost. At least to start.