Advocate I

So I have been planning different aspects of this build for a fairly long time and have finally started building it.

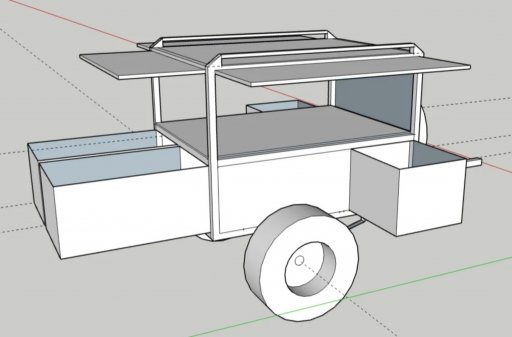

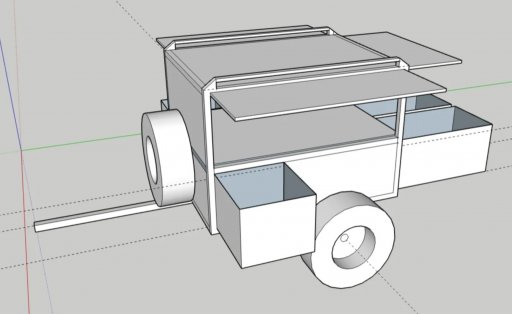

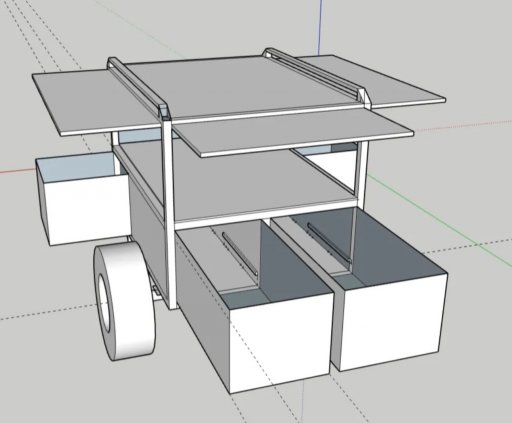

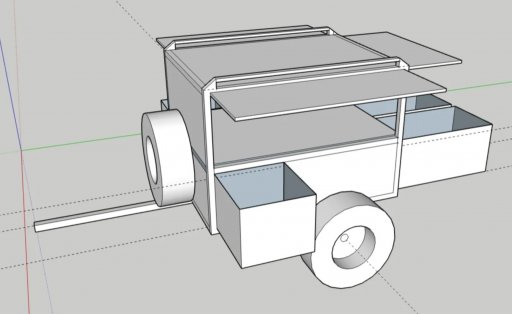

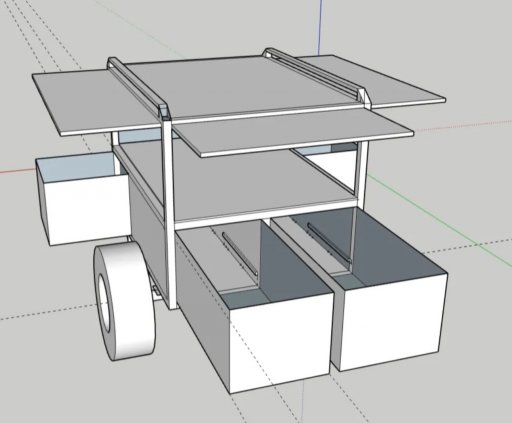

I started out by making some drawings up to get an idea of materials used and a rough finished weight ( guesstimation before getting to far in and realizing it's way too heavy lol).

I keep going through the drawings and finding little things to change here and there that have clearance issues or material changes, but I think I have it all worked out and decided to start. Basically my drawings are rough and are not the final product.

The rear will have 2 slide out platforms ( not drawers) that will run a 48" locking drawer slide, the sides I may turn into 1 more 48" slide as well but am also considering just leaving it as an open compartment.

The top half will be a large open compartment accessible from all sides for storing larger gear like tents, Jack's, traction aids, shovels, etc.

I also planed a roof rack for the top so I can haul kayaks, mount an awning, as we as my camp shower.... and in the future may also add a RTT up there... we will see.

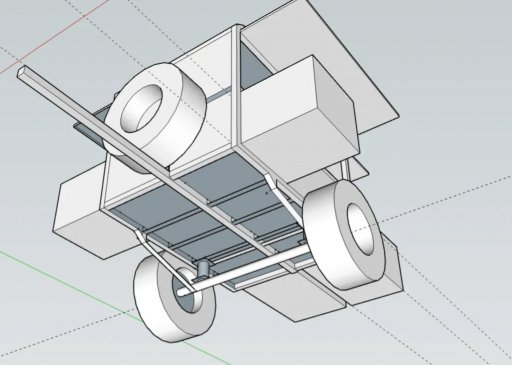

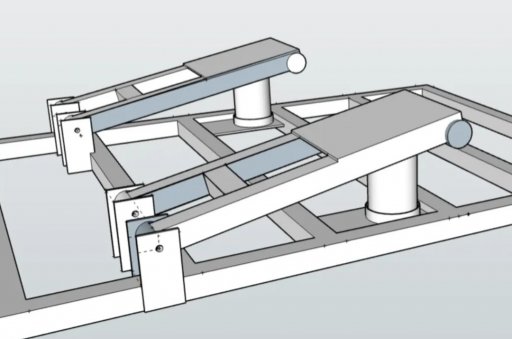

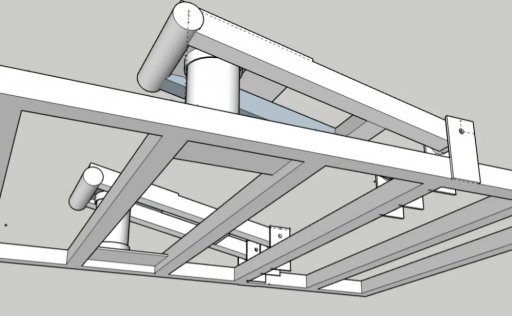

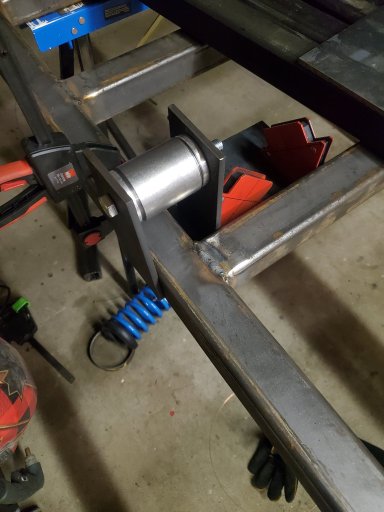

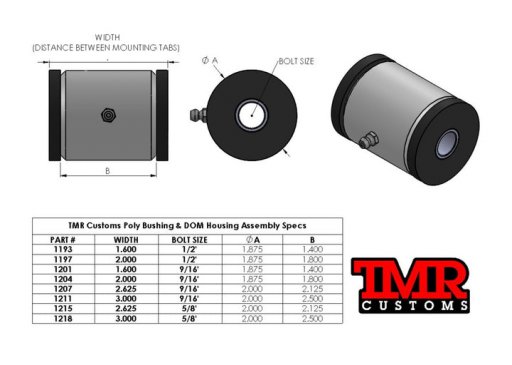

I have decided to try my hand at building and independent suspension system ( which the drawing shows very poorly because the drawings weren't really for designing suspension in my mind). So ha have a bit more planning to do around that.

The structure of the main base of the trailer may be a bit overkill but in my mind it shouldn't bent or twist causing issues later on down the road.... time will tell.

I started out by making some drawings up to get an idea of materials used and a rough finished weight ( guesstimation before getting to far in and realizing it's way too heavy lol).

I keep going through the drawings and finding little things to change here and there that have clearance issues or material changes, but I think I have it all worked out and decided to start. Basically my drawings are rough and are not the final product.

The rear will have 2 slide out platforms ( not drawers) that will run a 48" locking drawer slide, the sides I may turn into 1 more 48" slide as well but am also considering just leaving it as an open compartment.

The top half will be a large open compartment accessible from all sides for storing larger gear like tents, Jack's, traction aids, shovels, etc.

I also planed a roof rack for the top so I can haul kayaks, mount an awning, as we as my camp shower.... and in the future may also add a RTT up there... we will see.

I have decided to try my hand at building and independent suspension system ( which the drawing shows very poorly because the drawings weren't really for designing suspension in my mind). So ha have a bit more planning to do around that.

The structure of the main base of the trailer may be a bit overkill but in my mind it shouldn't bent or twist causing issues later on down the road.... time will tell.

Attachments

-

157.2 KB Views: 54

-

184.1 KB Views: 52