Advocate I

i’m looking for feedback and advice on the best materials for our setup. We have a 2004 LWB Mitusbishi Pajero (Montero/Shogun) with a 2nd and 3rd row seat delete. We are going to be using the vehicle for extended on and off road travel throughout Europe and North Africa in a variety of urban and wilderness environments. The truck is also our daily driver that we use with two adults, and two dogs.

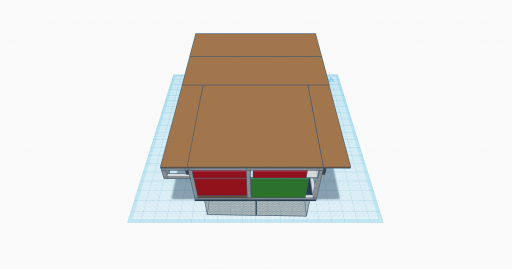

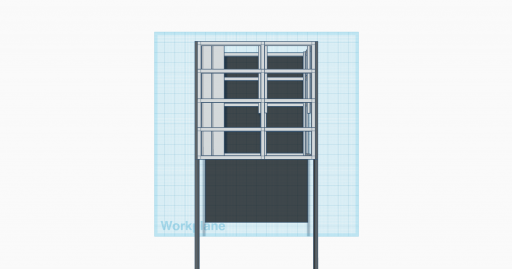

We are planning a modular and secure setup that can be (de)installed quickly and easily. After a year in lockdown we want to get something built quickly so that we can enjoy the warmer weather, while also maximising our ability to customise our setup over time. The ultimate goal is to build a drawer system with a sliding top, but the immediate goal is to build a basic box that we can slide our Plano boxes under, with extending rails on top so that we can lay out a bed for us and the hounds and get out into the mountains.

We travel light - camping and hiking kit, standard recovery gear, compressor, and don’t yet have but are planning to buy a fridge. We want to maintain access to the underfloor storage if possible, but concede that anything we build into the cargo area may make that difficult. Short term may not be a problem, but building in drawers likely means we will lose ease of access, so it would be more likely to house a house battery setup in future.

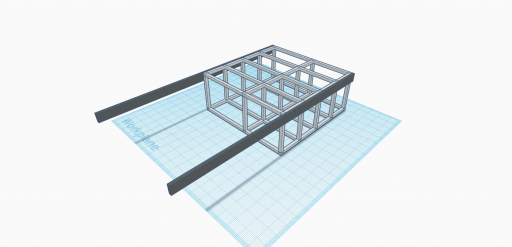

There seem to be two primary building materials for the frame — 8020 aluminium extrusion, and square aluminium tubing with ABS connectors. We have neither the skills or ease of access to a shop to weld. We have a mitre saw and aluminium blade, so we can cut either to length as required. I’ve thoroughly researched the options and it seems that the primary considerations are:

i’m curious to hear from others who’ve been this route, including any feedback on choosing the right profile for building a cargo solution that can take up to 200kg / 440lb (two humans and two big dogs) sleeping on top.

We are planning a modular and secure setup that can be (de)installed quickly and easily. After a year in lockdown we want to get something built quickly so that we can enjoy the warmer weather, while also maximising our ability to customise our setup over time. The ultimate goal is to build a drawer system with a sliding top, but the immediate goal is to build a basic box that we can slide our Plano boxes under, with extending rails on top so that we can lay out a bed for us and the hounds and get out into the mountains.

We travel light - camping and hiking kit, standard recovery gear, compressor, and don’t yet have but are planning to buy a fridge. We want to maintain access to the underfloor storage if possible, but concede that anything we build into the cargo area may make that difficult. Short term may not be a problem, but building in drawers likely means we will lose ease of access, so it would be more likely to house a house battery setup in future.

There seem to be two primary building materials for the frame — 8020 aluminium extrusion, and square aluminium tubing with ABS connectors. We have neither the skills or ease of access to a shop to weld. We have a mitre saw and aluminium blade, so we can cut either to length as required. I’ve thoroughly researched the options and it seems that the primary considerations are:

- materials cost (extrusion vs tube)

- connectors cost (extrusion fittings can be expensive)

- strength to weight ratio (extrusion is heavier but considerably stronger)

- modularity (there are significantly more options with extrusion, and if we plan it right, we can add components to it over time)

- ease of modification (extrusion framing requires more consideration than tubing)

i’m curious to hear from others who’ve been this route, including any feedback on choosing the right profile for building a cargo solution that can take up to 200kg / 440lb (two humans and two big dogs) sleeping on top.