Last summer for my birthday I was given a Viair Heavy Duty OBA kit. supposedly these are "ready to install"

for my purposes i threw out most of the kit outside of the compressor, hoses and tank. If I could do it again I would piecemeal the whole thing instead of the kit, route. The in box kit would have been great for a basic truck install but for the Jeep, with limited space challenges, more customization needed done.

basic run down

I knew I wanted a 2.5 gal tank in the Jeep for Bike trips/camping trips but did not want it

A.mounted to roll bar

B.to relocate muffler and place there

C.in the storage bin in place of bin,

D. completely exposed

I looked at a few options specifically Riverraider and Klein and decided to sketch something up and proceeded to re-locate my Evap over my axle to free up some space

I did the drawign with it with Sketchup, a hard ruler and notebook.

next step was a mockup. I made a template of each of the pieces using tape as "welds" and bolted it in place

next i cut steel adjusted and started welding things together

I knew that i wanted some bends in place of welds (or in conjunction with) so i used my trusty harbor freight press and a piece of angle with another bit of steel welded in the valley as a press brake this made making small bends SO much easier than the typical vise/BFH method

from here it was test fit, final weld, drill, paint and install. thank god for grinders and paint.

its not 100% perfect but works and is tucked far up enough that it has not been an issue in the Northeast and its been great for flat tires at Mountain Creek Bike park, really has sped up swapping out tubes. oh and its not to bad with the 33" tires either. ive done all 5 of mine, and then another set of 35s no problems.

for my purposes i threw out most of the kit outside of the compressor, hoses and tank. If I could do it again I would piecemeal the whole thing instead of the kit, route. The in box kit would have been great for a basic truck install but for the Jeep, with limited space challenges, more customization needed done.

basic run down

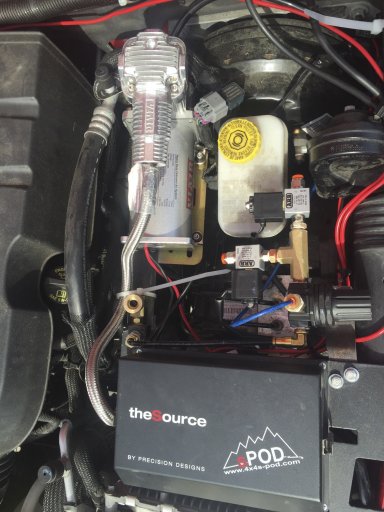

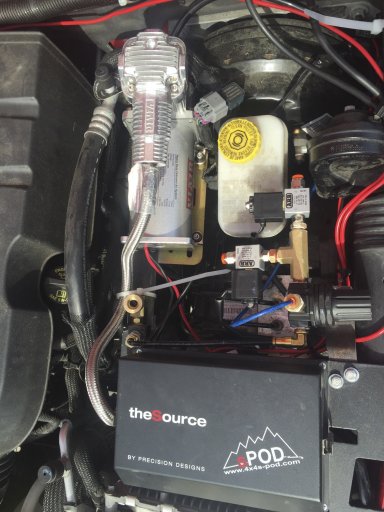

- The compressor is mounted to a Metalcloak ARB bracket drilled to fit,

- A 6 port manifold is then bolted to another piece of material connected to the end of that.

- on the manifold from front to back, Plug, In from compressor, Pressure switch wired to sPOD, Out to tank, Out to Regulator for ARBs, and a chuck

I knew I wanted a 2.5 gal tank in the Jeep for Bike trips/camping trips but did not want it

A.mounted to roll bar

B.to relocate muffler and place there

C.in the storage bin in place of bin,

D. completely exposed

I looked at a few options specifically Riverraider and Klein and decided to sketch something up and proceeded to re-locate my Evap over my axle to free up some space

I did the drawign with it with Sketchup, a hard ruler and notebook.

next step was a mockup. I made a template of each of the pieces using tape as "welds" and bolted it in place

next i cut steel adjusted and started welding things together

I knew that i wanted some bends in place of welds (or in conjunction with) so i used my trusty harbor freight press and a piece of angle with another bit of steel welded in the valley as a press brake this made making small bends SO much easier than the typical vise/BFH method

from here it was test fit, final weld, drill, paint and install. thank god for grinders and paint.

its not 100% perfect but works and is tucked far up enough that it has not been an issue in the Northeast and its been great for flat tires at Mountain Creek Bike park, really has sped up swapping out tubes. oh and its not to bad with the 33" tires either. ive done all 5 of mine, and then another set of 35s no problems.