Member III

Well, it seems like it is time for another build thread. So of you might remember my Jeep Wrangler build or my Jeep Gladiator build, this time around is a full size truck in the form of a 2022 RAM Power Wagon. The decision to go to a full size truck was based on a couple of things. First, with the wife, a kid and two dogs, the Jeeps were really not big enough to comfortably hold us all. Secondly, the Jeeps were less than ideal on long overland trips where you are driving 10+ hours. Especially when pulling a trailer.

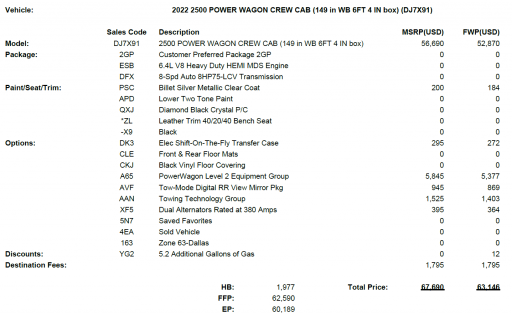

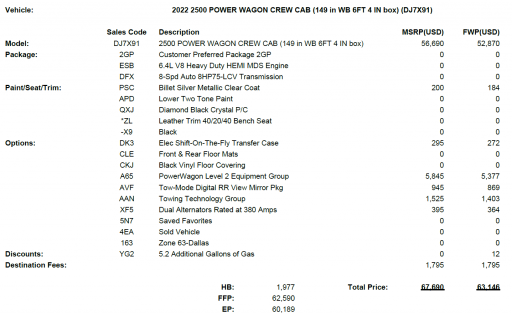

So on Veteran's Day 2021 I pulled the trigger and ordered a factory built 2022 Power Wagon with the following options from Mark Dodge in Lake Charles, LA :

The Truck was built on Jan 18th 2022 and I flew down to picked it up on Feb 11th. The final MSRP price when delivered was $70k and some change. My price from Mark Dodge was $59,669.

After visiting with family down in Arkansas I made the 863 mile single day trip back to Colorado. It took 14 hours and 2.5 tanks of gas. I averaged 12.5mpgs on that trip running about 80mph for long stretches of it.

Here it is in stock form at home in Colorado...

So on Veteran's Day 2021 I pulled the trigger and ordered a factory built 2022 Power Wagon with the following options from Mark Dodge in Lake Charles, LA :

The Truck was built on Jan 18th 2022 and I flew down to picked it up on Feb 11th. The final MSRP price when delivered was $70k and some change. My price from Mark Dodge was $59,669.

After visiting with family down in Arkansas I made the 863 mile single day trip back to Colorado. It took 14 hours and 2.5 tanks of gas. I averaged 12.5mpgs on that trip running about 80mph for long stretches of it.

Here it is in stock form at home in Colorado...