Influencer III

- 4,518

- First Name

- Brandon

- Last Name

- Eberhardt

- Member #

-

20143

- Ham/GMRS Callsign

- KE0JBH

- Service Branch

- Air Force 02-18

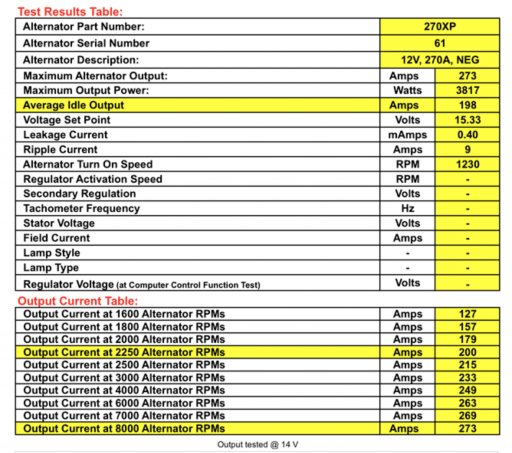

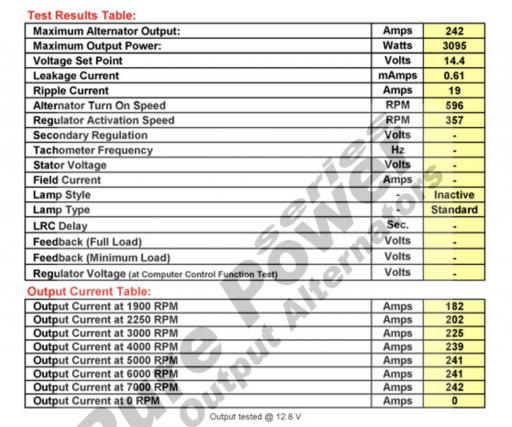

just wondering if anyone has experience or fitted a high idle switch for gas rig for winching. My GX470 has a pretty inemic alternator stock, so going to replace it, but I know a lot of rigs use a high idle switch to help reduce the strain. I can't seem to find much on installing these on gas motors, especially on the GX(lol go figure).

Am I missing something and it's not needed? or is it too difficult with a throtle by wire?

Thanks

Am I missing something and it's not needed? or is it too difficult with a throtle by wire?

Thanks