Ok, let's get moving on some of the related aspects of the winter project mode....

So, first off - I've used these Monoprice cases for several applications. I think this company mostly sells tech stuff, so the cases are kind of an afterthought for transporting tech stuff. But they're really good prices compared to Pelicans, and better quality than the HF ones. I've had one on the roof of the Raider for 2-3 years now (holding my traction boards) and it's held up well. In any case, they were on sale over Chrismas for even less than the normal price, so I grabbed one in a size I thought would work for this swing-out.

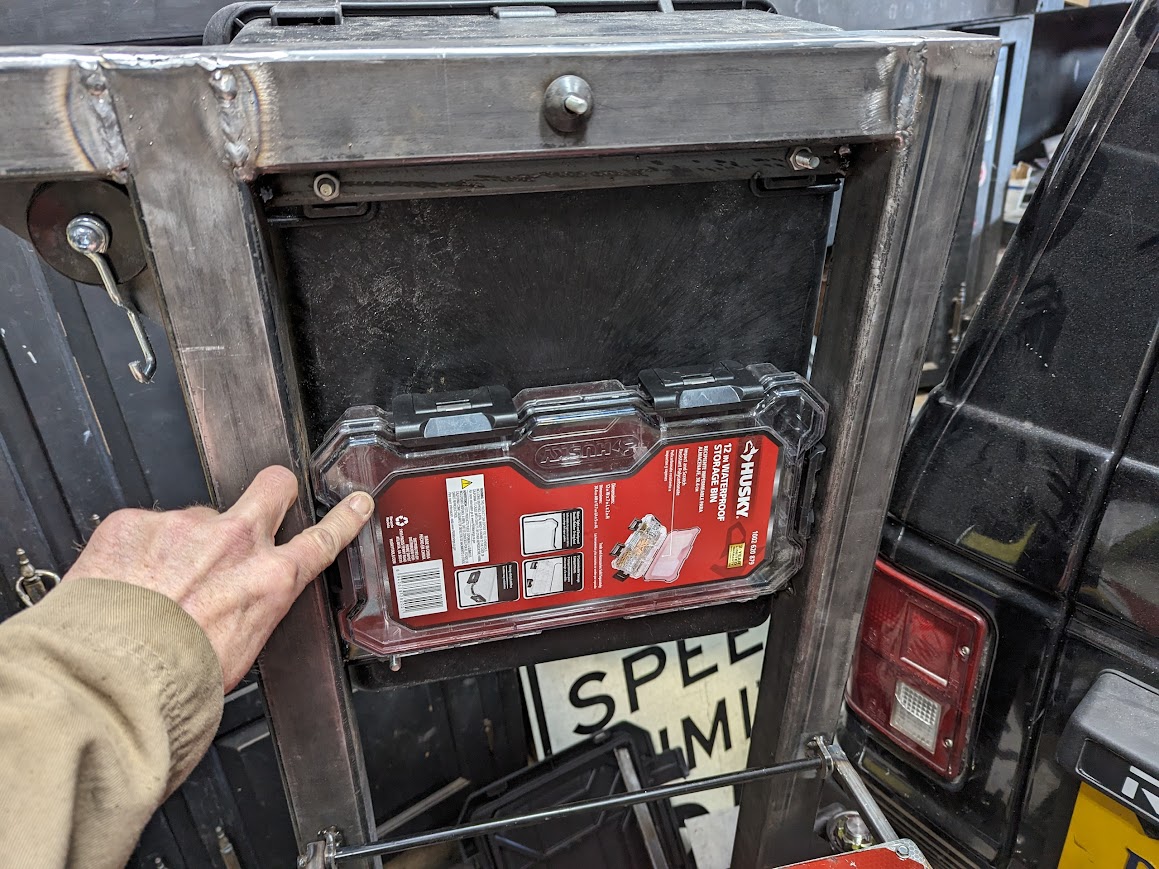

At one point I was thinking about doing a full-length case on the back and relocating the license plate, but changed my mind and decided to go with a smaller one so I wouldn't have to do that. After much measuring and test-fitting, we have this now:

The spatial placement somewhat annoys me but this truck isn't about being pretty, it's about function. In any case, I chose this case size both for fit and because I knew it would fit two of these nifty snowboard binding cases (which I've gotten a bunch of from the ski shop I work at part-time, over the past few years. They'll be good both for separating gear, and for keeping it from rattling around (I think I'm going to use this as a recovery gear case, by the way)..

Meanwhile, on the backside there's a cavity of sorts between the box and the fold-down table, and I"m thinking of putting some kind of small storage in there. Haven't found quite the right case to put there, but something like this:

--break--

it's cold this week, which makes garage work less fun. Here's some cold Sequoia pics.

ok, where was I? Ok, so as another part of the the rack, I want to put a propane tank on it so I can stop buying the little 1lb cans. So I got a 5lb tank. I was going to build a mount for it myself, but found a guy on etsy that builds them for a very reasonable price (less than most of the other "overland" brands I've found out there). Though I prefer to build my own stuff, sometimes I like to just buy something decent that looks good if the price is less than my time is worth lol. So I picked up this:

I'll probably mount it up above the gear box, but not sure exactly how I'm going to position it yet, we'll see.

---

oh, the original rear wiper snapped off a while back. I ordered a new one off ebay and it came in, from Korea of course, with Hyundai badging (for the Galloper, which is the same truck)

Also was watching Jack Ryan on Amazon and got a chuckle when someone driving this Gen1 Pajero broke down haha...

---

So the other project is the new sleeping/gear platform inside. YOu may recall I had one made of wood that I kind of did as a prototype. I didn't really like the setup for sleeping, or for gear, so decided to do something a bit bigger and in metal. So after a bit of welding and 15 feet of angle iron, this is where I'm at.

It's pretty stout. It's set up so one large foot locker case can go under it, and another next to it, and will have a wood top to it for a platform

You may also notice that the passenger seat is flipped around backwards. More on that later :)